ABB SNAT-0713 SCL Electronic Load Equipment

ABB SNAT-0713 SC

1. Overview

The ABB SNAT-0713 SCL is a high-current electronic load device designed for industrial automation, widely used in fuel cell R&D and testing. It supports multiple operating modes, including Constant Current (CC), Constant Voltage (CV), Constant Resistance (CR), and Constant Power (CP), with configurable under-voltage and overcurrent protection values. Additionally, it enables combined modes such as CC+CV and CR+CC+CV. Equipped with MPP tracking, energy storage discharge testing, and internal resistance measurement, this device is ideal for high-precision, high-stability testing scenarios.

2. Specifications

- Input resistance: >50 kΩ (when load input is off).

- Input power: Refer to model overview.

- Parallel operation: Up to 5 units can be connected for master-slave operation.

- Max input voltage: Vmax.

- Min input voltage: Vmin.

- I/O voltage: Refer to model overview.

- Vin-PE (Negative load input – PE): Max 60 V.

- Vin+PE (Positive load input – PE): Max 60 V.

- Rated power: -1.2 %/°C (at Ta=21°C).

- Derating: -1.2 %/°C (at Ta=21°C).

- Ambient temperature: 23±5°C.

- Max current: 1200 A (SCL-std configuration).

- Max voltage: 40 V (SCL604 model).

- Max power: 600 W (SCL604 model).

- Rise/Fall time: 2/10/100 ms (selectable).

- Input capacitance: 16 μF (SCL604 model).

- System AC voltage: 1/N/PE AC 230V 50…60Hz.

- System power consumption: 70 VA.

- System noise: 67 dB(A).

- Weight: 16 kg (SCL604 model).

- Mounting dimensions: 19″, 2U/SCL_M1.

3. Key Features

- Load waveform curves: In CC/CV/CR/CP modes, the List function generates curves with up to 300 segments, each with customizable sampling time.

- Rectangular function: Simplifies rectangular waveform generation via absolute time and amplitude inputs.

- PWM function: Allows manual adjustment of frequency and duty cycle for two amplitude levels.

- Waveform modulator: In CC/CV mode, superimposes sine, square, triangular, or arbitrary waveforms onto a base signal (constant=1, setpoint=1024 memory).

- MPP tracking: Combines scan and track sub-functions at adjustable intervals to plot V/I and V/P curves, displayed on the user interface.

- Energy storage discharge test: Supports CC+CV discharge, maintaining voltage until a defined minimum current is reached.

- Internal resistance test: Measures DC resistance of connected DUTs (e.g., batteries) per standards like DIN EN 61951 and DIN EN 61960.

- Data logging: Synchronously records voltage/current at set intervals (up to 40,000 data points).

- Trigger modes: External, common, manual, voltage, or current triggers.

- Watchdog: Automatically disconnects load input if no reset occurs after a delay during digital remote operation.

- Non-volatile memory: Stores active settings for quick reloading.

4. Structure & Components

- Mechanical design: Standard 19-inch rack-mount (2U height); desktop or cabinet installation (no additional kits required).

- Load terminals: Flat solid copper bars with M12 screws (max 2 cable lugs per side, 150 mm² contact area each).

- Parallel connectors: Options include SCL08 (2 units), SCL09 (3 units), SCL10 (4 units), and SCL11 (5 units).

- I/O ports: Standard analog/digital interfaces for control, status signals, and triggers.

- Isolated I/O (SCL06 option): Current-isolated analog ports prevent ground loops, enabling bipolar voltage testing.

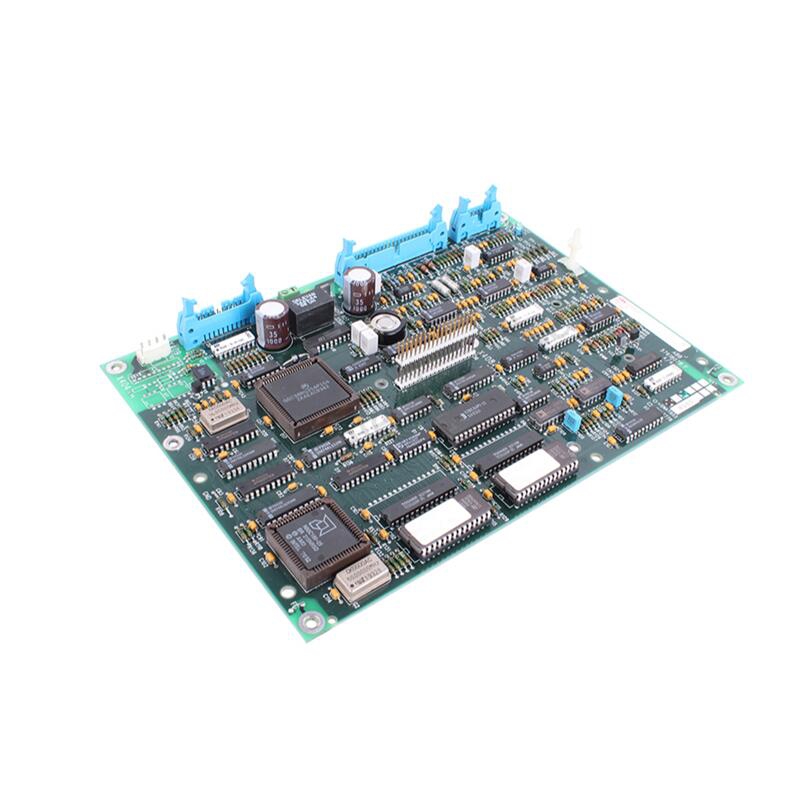

- Control board: SNAT603CNT 61007041 supports digital I/O (15V DC–60V DC, 120 VAC/125V DC, 240 VAC).

5. Applications

- Fuel cell testing: High-current evaluation for fuel cells.

- Industrial automation: Power supply control for factory automation, machinery, and process control systems.

- Energy storage testing: Discharge functionality for ESS performance validation.

- Battery testing: Complies with battery/accumulator standards.

- Smart grids: Monitors and controls power equipment.

6. Installation & Maintenance

- Installation: Tool-free 19-inch rack or bolt mounting.

- Maintenance: Includes factory calibration certificate (FCC) per DIN EN ISO 9001; free recalibration during warranty (if registered).

- Connectors: Parallel kits (SCL08–SCL11) for multi-unit setups.

- Data interfaces: Enables seamless data transfer/storage.

- Triggers: External/common/manual/voltage/current triggers for automated workflows.

———————————————————————————————————————————

If you would like to learn more about our products and services, please feel free to contact us at any time!

Sales Manager : Jinny

Email : sales5@xrjdcs.com

Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

- Our company is an offline entity and can issue 13% VAT invoices.

- Customers requiring invoices must request them explicitly. Product prices listed are exclusive of tax.

- Shipping methods: SF Express, Deppon, EMS. If other couriers are needed, please contact us before purchase.

- Please inspect the package upon delivery before signing. No returns or exchanges will be accepted for damages discovered after signing without inspection.

- If you find the same product offered at a lower price by another supplier, we are willing to match the price and offer further discounts.

- All products are in stock and ready for immediate shipment. Accessories come with a 3–6 month warranty, while new original products have a 1-year warranty.

- Receiving goods: Upon delivery, please confirm the outer packaging is intact before signing. If shortages or missing items are found during inspection, you may refuse delivery and contact us promptly.

- Due to the wide variety of models, not all are listed. If you can’t find the model you need, feel free to contact us via email or phone.

Warranty Terms:

- Warranty Period: Most products come with a limited warranty, typically 1 year or longer, depending on the product type.

- Coverage: Warranty covers defects in materials or workmanship. Repairs or replacements are free for faults under normal use.

- Exclusions:

- Damage caused by mishandling (e.g., drops, water exposure, or misuse).

- Unauthorized repairs or modifications.

- Failures occurring after the warranty period expires.

- Process: To claim warranty service, provide proof of purchase (e.g., invoice) and contact customer service. Return the product to the designated repair center as instructed.

- Fees: Repairs within warranty are free, but out-of-coverage services may incur charges.