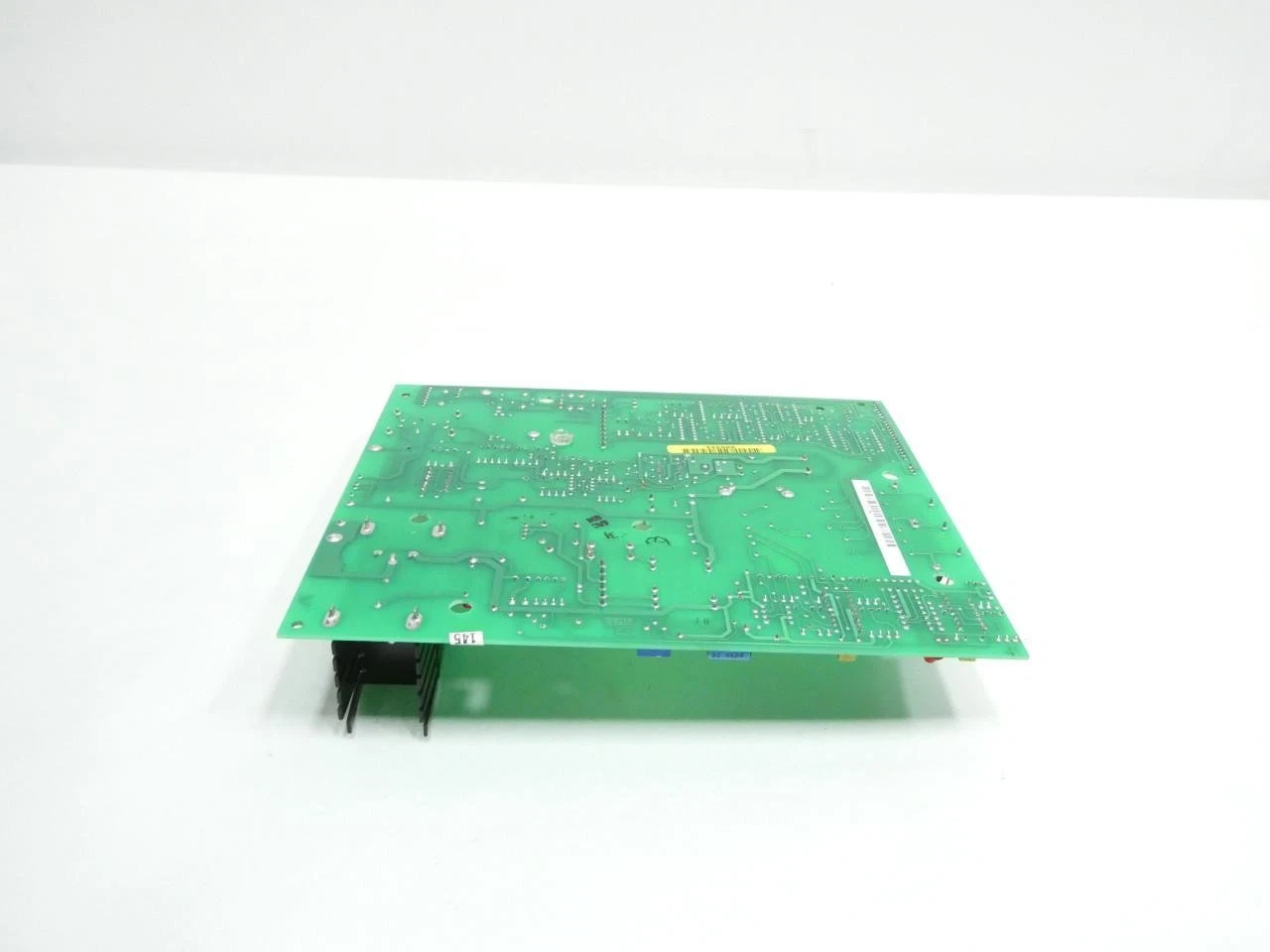

Eaton 15-871-5 Filter Product

Eaton 15-871-5

Eaton 15-871-5 is an industrial filter product from the Eaton series, specifically designed for the purification of oil, gas, or hydraulic systems. Featuring a modular structure, this model allows flexible configuration of filter elements, bags, or screens based on on-site requirements, enabling efficient interception of impurities such as particles, oil mist, moisture, and VOCs.

Key Technical Specifications

- Filtration Precision: Optional 1 µm–5 µm grades, meeting international cleanliness standards such as ISO 4572 (β ≥ 200).

- Operating Temperature Range: -40 °C to +150 °C, suitable for most industrial oils and lubricants.

- Maximum Working Pressure: Approximately 4,568 psi (≈ 31.5 MPa), with a test pressure margin of 6,525 psi (≈ 44.9 MPa).

- Flow Rate Range: 5,200 L/min (gas) or 130 L/h–1,800 L/h (liquid).

- Construction Materials: The housing is made of stainless steel or high-strength engineering plastic. Filter elements are available in sintered bronze, metal mesh, or composite fiber materials, offering corrosion and high-temperature resistance.

Product Features

- Modular Design: Filter elements, bags, and screens can be quickly replaced on-site, minimizing downtime.

- High Interception Efficiency: Combined star-pleated filter media and multi-layer filtration structure deliver excellent particle capture and oil mist separation performance.

- High Pressure & Temperature Resistance: Complies with the harsh operating conditions of industrial hydraulic systems.

- Easy Maintenance: Removable filter elements eliminate the need to disassemble the entire filter body, reducing maintenance costs.

- Multi-Medium Compatibility: Suitable for mineral oils, synthetic oils, lubricants, and some water-based emulsions.

Structure & Components

- Housing: Stainless steel or engineering plastic construction, equipped with flange or threaded connections for easy pipeline integration.

- Filter Element/Bag: Sintered bronze filter elements (for high-pressure applications) or composite fiber filter bags (for standard applications) selected based on the medium.

- Seals: High-temperature and oil-resistant O-rings ensure leak-proof performance.

- Valve Body (Optional): Equipped with a bypass valve or blowdown valve for on-line cleaning or bypass operation.

Typical Application Areas

- Hydraulic Systems: Industrial machinery, mobile equipment, and marine hydraulic circuits.

- Gas Compression Systems: Compressed air dryers, pre-filtration, micro-filtration, and activated carbon filtration combinations.

- Lubricating Oil Circuits: Gearboxes, transmissions, and bearing lubrication loops.

- Process Industry: Chemical, petroleum, food processing, and other applications with strict requirements for oil cleanliness.

Installation & Maintenance Guidelines

- Pre-Installation Inspection: Ensure flange surfaces are flat, bolt holes are aligned, and appropriate gaskets are used.

- Flow Direction Confirmation: Both filter elements and bags are marked with inlet and outlet flow directions; ensure correct fluid flow.

- Initial Flushing: Prior to first use, perform low-pressure flushing to remove manufacturing residues.

- Regular Replacement: Replace filter elements based on pressure drop or differential pressure alarms. Composite filter bags are typically replaced every 3–6 months.

- Maintenance Records: Document replacement dates, service life, and differential pressure values to facilitate service life evaluation and spare parts planning.

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

As a professional company deeply rooted in the industrial automation sector, Xiamen Xingruijia Import and Export Co., Ltd.

has been committed to providing customers with high-quality and highly reliable industrial control system solutions.

We are authorized distributors of products from world-renowned brands such as GE (General Electric) of the United States and YOKOGAWA of Japan, which are widely applied in multiple industries including petrochemicals, power generation, and metallurgy.

Leveraging our extensive industry experience and professional technical team, we can tailor the most optimized automation solutions for customers, helping them enhance production efficiency and product quality.

We have the hard-to-find obsolete spare parts you urgently need!

Whether you can’t find the parts through inquiries or struggle to purchase them elsewhere, please feel free to contact us.

We offer competitive prices, product quality guarantees, value-added services, and sufficient inventory.Inquiry is always welcome—we will provide you with preferential pricing!