Welcome to our websites!

EMERSON 1C31113G01 (Input/Output) Module

EMERSON 1C31113G01

EMERSON 1C31113G01 is an I/O (Input/Output) module under the Emerson product series. It is commonly used in platforms such as industrial automation, Distributed Control Systems (DCS), and Programmable Logic Controllers (PLC).

It is compatible with mainstream control systems like Emerson Ovation and SmartLogic, supporting the collection of on-site sensor signals and the control of actuators.

Main Technical Parameters

| Parameter | Description |

|---|---|

| Operating Voltage | 220 V DC/AC |

| Operating Temperature Range | -5 °C ~ +95 °C |

| Communication Interfaces | Ethernet, RS-485, USB |

| Signal Types | Analog (Voltage/Current) and Digital (Switch) |

| Analog Input Range | ±20 mV (13-bit resolution) |

| Output Mode | Relay output (16 channels, rated 10 A) |

| Modular Design | Supports hot swapping for easy on-site maintenance |

| Protection Level | Complies with industrial dust-proof and water-proof standards, and resists electromagnetic interference |

Product Features

- High Reliability: Adopts industrial-grade components, with anti-interference, high-temperature resistance, and anti-vibration capabilities, suitable for harsh environments.

- Modular/Hot-Swappable: Enables quick replacement, reducing downtime.

- Multi-Functional: Compatible with various analog/digital signals and supports multiple communication protocols (such as Modbus, Ethernet/IP).

- Easy Configuration: Comes with user-friendly human-machine interface and programming tools for convenient on-site debugging.

- High Precision: 13-bit ADC provides delicate analog quantity collection.

Structure and Composition

- Power Supply/Voltage Regulation Unit: Responsible for converting external power into the voltage required inside the module.

- Analog Front-End Circuit: Includes filtering, amplification, and protection circuits, used for processing sensor signals.

- Analog-to-Digital Converter (ADC): Converts analog signals into digital data (13-bit).

- Digital Input/Output Driver: Includes 16 relay output channels and digital input buffers.

- Communication Interface Board: Equipped with Ethernet, RS-485, USB, etc., for interacting with the upper-level system.

- Chassis and Heat Dissipation Structure: Features a metal or high-strength plastic housing, complying with IP rating protection standards.

Typical Application Fields

- Oil and natural gas production process monitoring

- Automation of chemical and metallurgical production lines

- Power systems (power generation, power distribution)

- Water treatment and environmental monitoring

- Food and pharmaceutical process control

- Any industrial control system that requires high-reliability I/O interfaces

Key Points for Installation and Maintenance

Pre-Installation Inspection

- Confirm that the power voltage and grounding meet the specifications.

- Check if the cabinet space meets the heat dissipation requirements.

Wiring

- Wire according to the markings in the module manual. Use shielded wires for analog signals and wires that meet the rated current for digital/relay outputs.

- Use bolts or quick terminals to ensure firm connection.

Communication Configuration

- Add the module address in the control system and set the communication protocol (e.g., Modbus TCP).

- Perform parameter calibration through the configuration software provided by Emerson.

Hot Swapping

Carry out hot swapping after the system is shut down or switched to safe mode to avoid instantaneous current impact.

Regular Maintenance

- Check the tightness of wiring and terminal corrosion every 6 to 12 months.

- Use the diagnostic function to monitor the self-inspection status of the module and replace faulty channels in a timely manner.

- Clean the dust inside the cabinet to ensure unobstructed heat dissipation channels.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

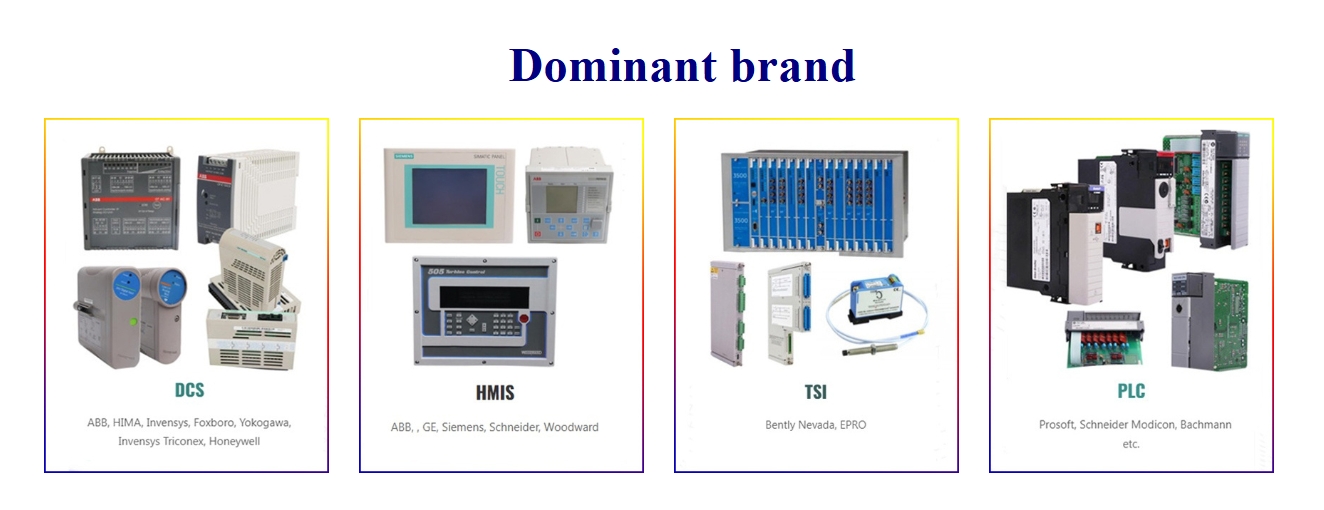

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Your Reliable Partner for Customized Automation Solutions

As a seasoned expert dedicated to automation technology, we have established ourselves as a trustworthy ally for businesses seeking tailored automation support. Leveraging decades of focused experience in the automation sector, we deliver comprehensive product portfolios and professional services, spanning core components like PLCs, DCS systems, and variable frequency drives (VFDs). Whether you need to optimize complex process control in the petrochemical industry or implement energy-saving solutions for motors in the power sector, our team excels at crafting solutions that align perfectly with your unique operational needs. Our products are recognized for consistent performance and exceptional reliability, all of which have been validated through rigorous international quality certifications.

Why Partnering with Us Adds Value to Your Business

- Superior Quality Assurance: Every product and solution undergoes strict quality checks to meet industry-leading standards, minimizing operational risks for your business.

- On-Time Delivery Commitment: We prioritize efficient supply chain management to ensure your orders are delivered promptly, avoiding delays in your production or project timelines.

- Extensive Range of Branded Components: We stock and supply a wide selection of parts from well-known, reputable brands, guaranteeing compatibility and durability.

- Expert Team & Advanced Testing Facilities: Our team of seasoned professionals, combined with state-of-the-art testing equipment, ensures every solution is fully validated before deployment.

- Ample Inventory Reserves: We maintain large inventory levels to meet your urgent needs, reducing lead times and keeping your operations running smoothly.

- 100% Genuine New Products: We strictly provide original, brand-new items—no refurbished or counterfeit products—ensuring the highest quality and long-term performance.

Write your message here and send it to us