Welcome to our websites!

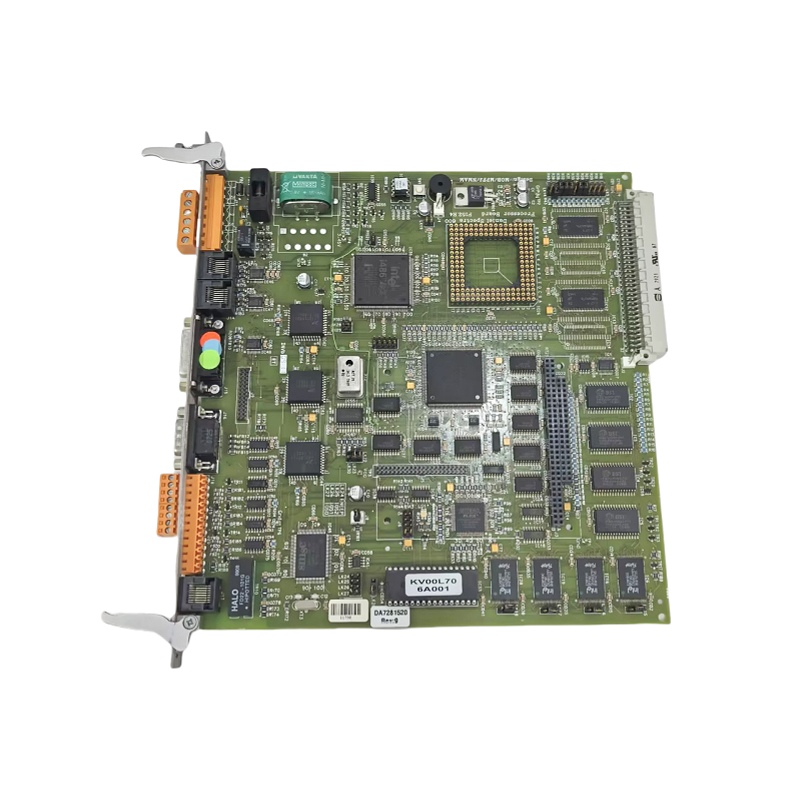

EMERSON DA7281520 P152 Particulate Monitor

Product Information of EMERSON DA7281520 P152

The DA7281520 P152 is a particulate monitor belonging to the P152 PLUS series under Emerson. It is specifically designed for continuous monitoring of particulate concentrations in flue gas, pipelines, and other industrial emissions. The product complies with global emission regulations, featuring high sensitivity, a wide measurement range, and reliable diagnostic functions, making it suitable for long-term online operation.

1. Main Technical Specifications

| Specification | Parameter |

|---|---|

| Measurement Range | 0 ~ 10 g/m³ (wider range optional) |

| Resolution | ≤ 0.01 g/m³ |

| Response Time | ≤ 5 s (T90) |

| Operating Temperature | -20 °C ~ +70 °C |

| Operating Pressure | 0 ~ 2 MPa (depending on on-site pipeline) |

| Power Supply | 24 V DC (120/240 V AC optional) |

| Communication Interface | HART, Modbus RTU, PROFIBUS, Ethernet (optional) |

| Output Signal | 4-20 mA, 0-10 V, relay output |

| Protection Class | IP66 (dustproof and waterproof) |

| Dimension | Approximately 210 mm × 140 mm × 300 mm |

| Weight | Approximately 5 kg |

2. Product Features

- High-Precision Particulate Detection: Adopts laser scattering technology, enabling stable measurement within a wide temperature and pressure range.

- Multi-Protocol Communication: Built-in HART device description, supporting fieldbus and Ethernet, facilitating integration into DCS/SCADA systems.

- Self-Diagnostic Function: Equipped with automatic self-inspection, sensor health monitoring, and fault alarm functions, reducing maintenance costs.

- Modular Design: The sensor, electronic module, and display panel can be quickly replaced, improving on-site maintenance efficiency.

- Durability: With IP66 protection class, it is suitable for harsh industrial environments (such as high temperature, corrosive gas, etc.).

- Flexible Output: Provides multiple output methods including analog quantity, relay, and digital communication, meeting different control requirements.

3. Structure and Composition

- Sensor Unit: Laser scattering particulate sensor, equipped with a protective filter and a calibration port.

- Electronic Control Box: Includes a signal processing chip, communication module, power management, and diagnostic circuit.

- Display Panel: Local operation interface, displaying real-time concentration, alarm status, and system diagnostic information.

- Mounting Bracket/Flange: Can be directly installed on pipeline flanges or brackets, with anti-vibration gaskets.

- Supporting Accessories: Includes HART adapter, remote I/O module, calibration gas interface, etc.

4. Typical Application Fields

- Power Industry: Monitoring of particulate emissions from coal-fired boilers and gas turbines.

- Iron and Steel Metallurgy: Online monitoring of high-temperature flue gas and dust removal systems.

- Chemical and Petrochemical Industry: Emission control of reaction kettles and distillation towers.

- Cement and Building Materials Industry: Kiln emission and dust control.

- Environmental Supervision: Continuous Emission Monitoring Systems (CEMS) for government or third-party monitoring stations.

5. Installation Key Points

- Site Selection: Ensure the sensor inlet is far from direct air flow, heat sources, and vibration sources, and maintain a sufficient sampling length (≥ 5 times the pipe diameter).

- Flange Connection: Use supporting flange gaskets to ensure tightness; tighten bolts evenly to prevent leakage.

- Power Supply and Grounding: The 24 V DC power supply needs to be filtered, and the equipment shell must be reliably grounded.

- Communication Wiring: Use shielded twisted pairs for HART/Modbus, and keep the wire length within the specified range (≤ 300 m).

- Calibration and Commissioning: Perform zero calibration and range calibration after the first installation, using calibration gas or standard particulate sources provided by the manufacturer.

6. Maintenance

- Regular Inspection: Check the protective filter and sensor optical window for dust accumulation or scaling every 3 to 6 months.

- Self-Diagnostic Log: View the equipment self-inspection report through HART or the local panel, and replace faulty components in a timely manner.

- Calibration Cycle: A complete calibration is recommended every 12 months; it can be shortened to 6 months under special working conditions.

- Spare Part Replacement: The sensor module, optical window, and electronic board are all hot-swappable spare parts, and the on-site replacement time is ≤ 30 minutes.

- Firmware Upgrade: Regularly check the firmware version released on Emerson’s official website; upgrading can improve measurement algorithms and communication compatibility.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

About Us

- Expert Technical Backup: Our technical team boasts over 5 years of hands-on experience in industrial control fields, ready to deliver tailored technical solutions and real-time support for your projects.

- Competitive Pricing Advantage: By maintaining long-term strategic partnerships with top-tier suppliers, we cut down intermediate costs to offer you cost-effective quotes without compromising product quality.

- End-to-End Considerate Service: From pre-purchase product consultation and customization advice to in-sales order tracking and post-delivery usage guidance, we cover every step to solve your concerns in advance.

- Diversified Product Portfolio: We provide a full range of industrial control equipment, such as programmable logic controllers (PLCs), human-machine interfaces (HMIs), servo amplifiers, frequency converters, and matching accessories—fully meeting your one-stop procurement needs.

After-Sales Service Commitment

- We stand behind our products with all-round after-sales protection: including fast fault repair (average turnaround time within 3 working days), 7×12 hours technical hotline support, and free on-site operation training for bulk orders. This ensures your industrial control systems run smoothly at all times.

- Dependable Product Quality: We collaborate exclusively with well-recognized domestic and international industrial control brands, all of which have passed strict quality certifications (such as CE, ISO9001). Our products feature stable performance and ultra-low failure rates, laying a solid foundation for your production.

- Proactive Technical Assistance: Beyond troubleshooting, our team proactively shares industry-specific technical insights and product upgrade information, helping you optimize equipment performance and reduce maintenance costs.

- Flexible Pricing Options: For long-term cooperative clients or large-volume orders, we offer customized pricing packages (such as seasonal discounts, bulk purchase rebates) to bring more value to your business growth.

- Personalized Service Experience: We assign a dedicated account manager to each client, who tracks your product usage status regularly and responds to your needs within 24 hours—making your after-sales experience more efficient and personalized.

Write your message here and send it to us