EMERSON KJ2201X1-HA1 Safety Terminal Block

EMERSON KJ2201X1-HA

1. Overview

2. Specifications

- Explosion Protection Rating: ATEX compliant, with a built‑in Intrinsically Safe design.

- Current Rating:Wiring Method: Screw compression type, supporting quick assembly and disassembly.

- Between Terminals A‑B: 30 mA (for low‑power signal circuits)

- Between Terminals A‑C: 1 A (for general power supply or control circuits)

- Operating Temperature Range: ‑25 °C ~ +85 °C (specifically dependent on the installation environment).

- Material: Flame‑retardant plastic housing, with high‑conductivity copper alloy contacts inside.

3. Product Features

- Intrinsic Safety: Minimizes energy output to prevent ignition of surrounding flammable gases.

- Seamless Compatibility with DeltaV: Plug‑and‑play functionality simplifies system integration and on‑site commissioning.

- High Reliability: Features vibration‑resistant and shock‑resistant design, suitable for harsh industrial sites.

- Modular Structure: Allows flexible combination of terminals with different current specifications based on on‑site requirements.

- Easy Maintenance: Screw‑type wiring facilitates quick inspection and replacement.

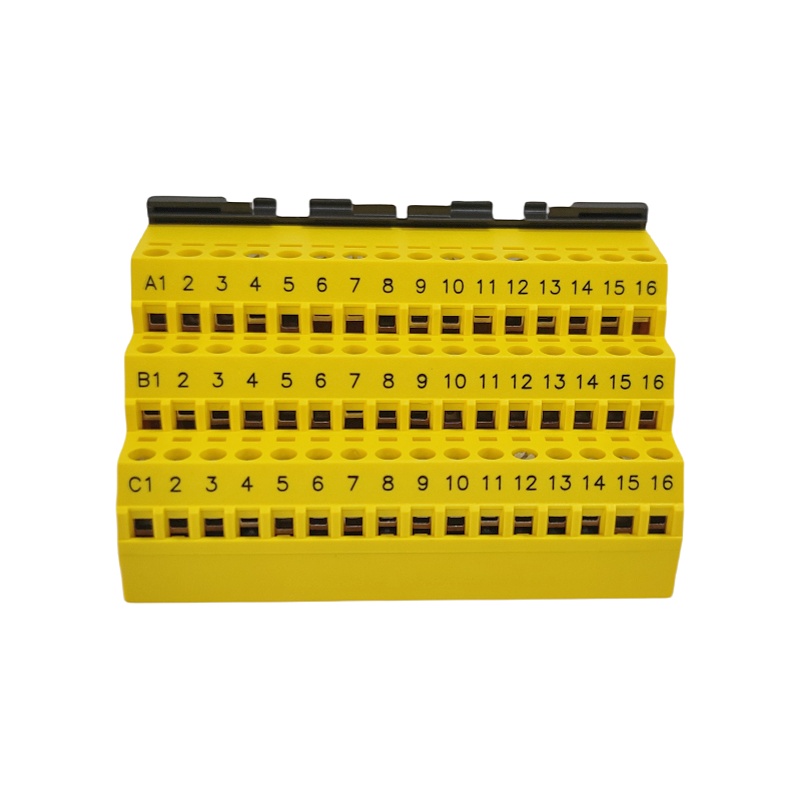

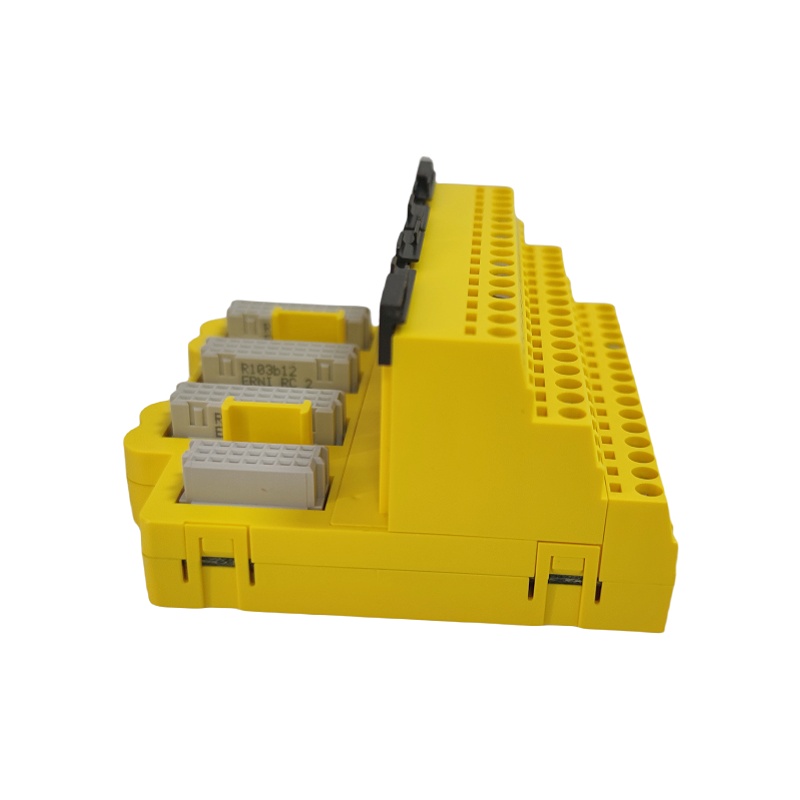

4. Structure and Composition

- Housing: Made of flame‑retardant plastic, providing protection and meeting explosion‑proof requirements.

- Terminal Block: Divided into three groups (A, B, C), each corresponding to different current ratings.

- Wiring Screws: Equipped with anti‑loosening design to ensure long‑term reliable contact.

- Identification Labels: Clearly mark terminal functions and current specifications for easy on‑site identification.

5. Application Fields

- Petrochemical Industry: Used for process control signal transmission in hazardous areas.

- Natural Gas and Oil Refining: Ensures safe wiring between explosion‑proof instrument panels and on‑site instruments.

- Pharmaceutical and Food Industry: Suitable for production lines that meet both hygiene and explosion‑proof requirements.

- Power and Energy Industry: Used for signal wiring in high‑risk environments such as substations and power distribution cabinets.

6. Installation and Maintenance

Installation

- Select an installation location that meets explosion‑proof requirements, and ensure the terminal block is away from interference sources such as high temperatures and strong magnetic fields.

- According to the wiring diagram in the product manual, crimp the corresponding cables to Terminals A, B, and C, and secure them with screws.

- Check the tightness of the wiring to ensure there is no looseness or incorrect connection.

Maintenance

- Regularly (recommended every 6 ~ 12 months) check the tightness of the screws and re‑tighten them if necessary.

- Clean the surface of the terminals to prevent dust and oil from affecting electrical conductivity.

- If terminal corrosion or damage is found, replace the corresponding module in a timely manner to avoid impacting system safety.

- Maintenance records should include inspection date, inspector, identified issues, and handling measures to meet safety audit requirements.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Frequently Asked Questions (FAQs)

Q: Are you operating as a trading company or a manufacturer?

A: We are a trading company—this is our core business model.

Q: Do you keep inventory in-house, or do you need to source goods from other suppliers?

A: We maintain a substantial inventory for immediate sale, and we also have our own dedicated warehouse to store these goods.

Q: Can you guarantee 100% original and brand-new products?

A: Without a doubt. You won’t find any plagiarized, counterfeit, or refurbished items here—only 100% original products.

Q: Do you offer outdated products, even those that are quite old?

A: Here’s how we handle it: If a new model is available to replace the old one, we’ll actively recommend the new model to you. If replacement isn’t feasible, we’ll assist with inspecting the old product to confirm it’s in good working condition. For any other usage-related conditions, we’ll always be transparent and share the full truth.

Q: How long is your typical lead time for delivery?

A: The lead time varies by stock status and order size: For in-stock goods, it usually takes 2-3 working days. For large-volume orders, you can expect a lead time of 5-7 working days after we receive your payment. For non-regular products (i.e., items not in our standard inventory), the ordering and delivery process typically takes 3-4 weeks or 6-8 weeks.