EMERSON KJ4001X1-BE1 Interface Module

EMERSON KJ4001X1-BE1

1. Product Overview

2. Key Technical Specifications

- Number of Channels: 8 digital I/O channels (8 single-ended or 4 differential)

- Input Voltage: 24 V DC (some models support 5 V DC)

- Output Current: 2 A (per channel)

- Local Bus Power Supply: 12 V DC @ 15 A (LocalBus Power)

- Power Consumption: 8 W (typical)

- Operating Temperature: -40 °C ~ +85 °C (some documents specify -20 °C ~ +60 °C)

- Protection Class: IP30 (dust-proof and protection against electric shock)

- Dimensions: Approximately 100 mm × 50 mm × 20-25 mm (about 4 × 2 × 1 inches)

- Weight: 0.7 ~ 0.9 kg

- Certifications: CE, UL, FM, ATEX II 3G Ex ec IIC Gc, etc.

- Interface: 8-wide I/O Carrier with Shield Bar (12P0818X072)

3. Product Features

- High Compatibility: Specifically designed for the DeltaV system, it can be directly plugged into the underlying I/O modules of the system.

- Signal Isolation and Shielding: Built-in shield bar and electrical isolation reduce EMI interference.

- Hot-Swappable: Supports on-site hot swapping, minimizing maintenance downtime.

- Multi-Signal Support: Can be configured as single-ended or differential input to meet different on-site wiring requirements.

- Durability: Complies with industrial safety standards such as IEC 61784-2 and ATEX, and is resistant to vibration, shock, and extreme temperatures.

- Simplified Wiring: Adopts a modular terminal arrangement, ensuring clear wiring and facilitating on-site debugging.

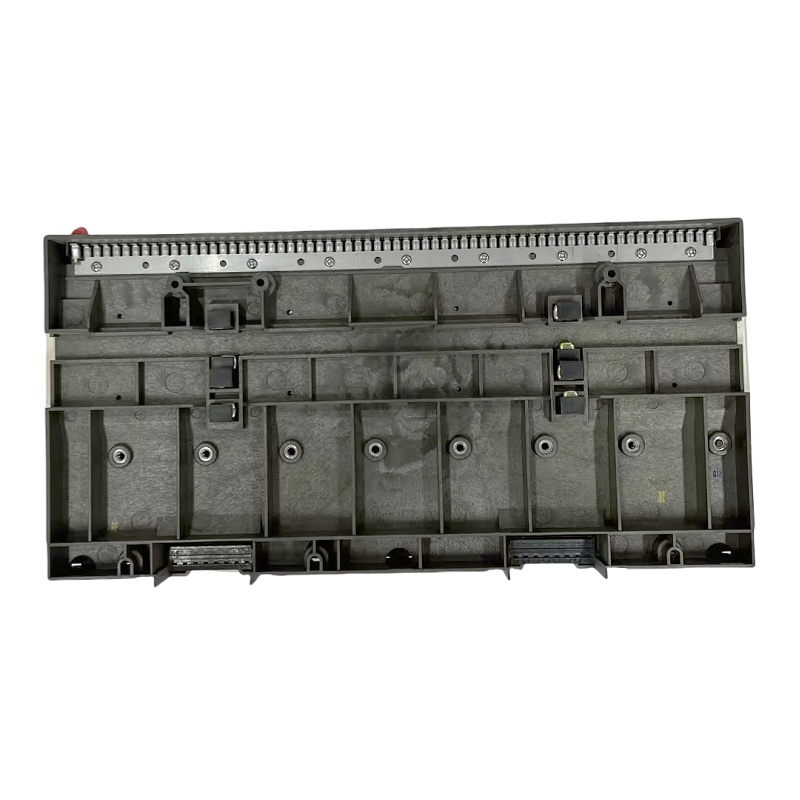

4. Structure and Composition

- Module Body: Features a metal housing, with internal components including an I/O terminal block, a shield bar, and a power distribution circuit.

- Terminal Block: Includes 8 digital input/output terminals (single-ended/differential optional), each with an identifier.

- Power Interface: Equipped with LocalBus power supply terminals (12 V DC) and overcurrent protection.

- Shield Bar: Located on the back of the module to reduce electromagnetic interference.

- Mounting Holes: Complies with DIN-rail standards for easy cabinet installation.

5. Typical Application Fields

- Large-scale power plants (power generation, combined heat and power)

- Petroleum and chemical industry (process control, pipeline monitoring)

- Pharmaceutical and biopharmaceutical industry (clean process control)

- Marine and offshore platforms (distributed control)

- Robotics and automated production lines (high-speed I/O interaction)

- Other industrial automation systems (e.g., iron and steel, papermaking, food and beverage)

6. Installation and Maintenance Guidelines

Step 1: Preparations

Step 2: Mechanical Installation

Step 3: Electrical Wiring

Step 4: Configuration

Step 5: Function Verification

Step 6: Regular Maintenance

- Check the tightness of terminals and the integrity of the shield bar every 6-12 months.

- Remove dust and check the grounding resistance.

- If an abnormality is found, replace the module using the hot-swapping function to avoid system shutdown.

7. Summary

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Frequently Asked Questions (FAQs)

Q: Are you operating as a trading company or a manufacturer?

A: We are a trading company—this is our core business model.

Q: Do you keep inventory in-house, or do you need to source goods from other suppliers?

A: We maintain a substantial inventory for immediate sale, and we also have our own dedicated warehouse to store these goods.

Q: Can you guarantee 100% original and brand-new products?

A: Without a doubt. You won’t find any plagiarized, counterfeit, or refurbished items here—only 100% original products.

Q: Do you offer outdated products, even those that are quite old?

A: Here’s how we handle it: If a new model is available to replace the old one, we’ll actively recommend the new model to you. If replacement isn’t feasible, we’ll assist with inspecting the old product to confirm it’s in good working condition. For any other usage-related conditions, we’ll always be transparent and share the full truth.

Q: How long is your typical lead time for delivery?

A: The lead time varies by stock status and order size: For in-stock goods, it usually takes 2-3 working days. For large-volume orders, you can expect a lead time of 5-7 working days after we receive your payment. For non-regular products (i.e., items not in our standard inventory), the ordering and delivery process typically takes 3-4 weeks or 6-8 weeks.