Welcome to our websites!

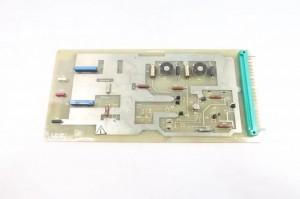

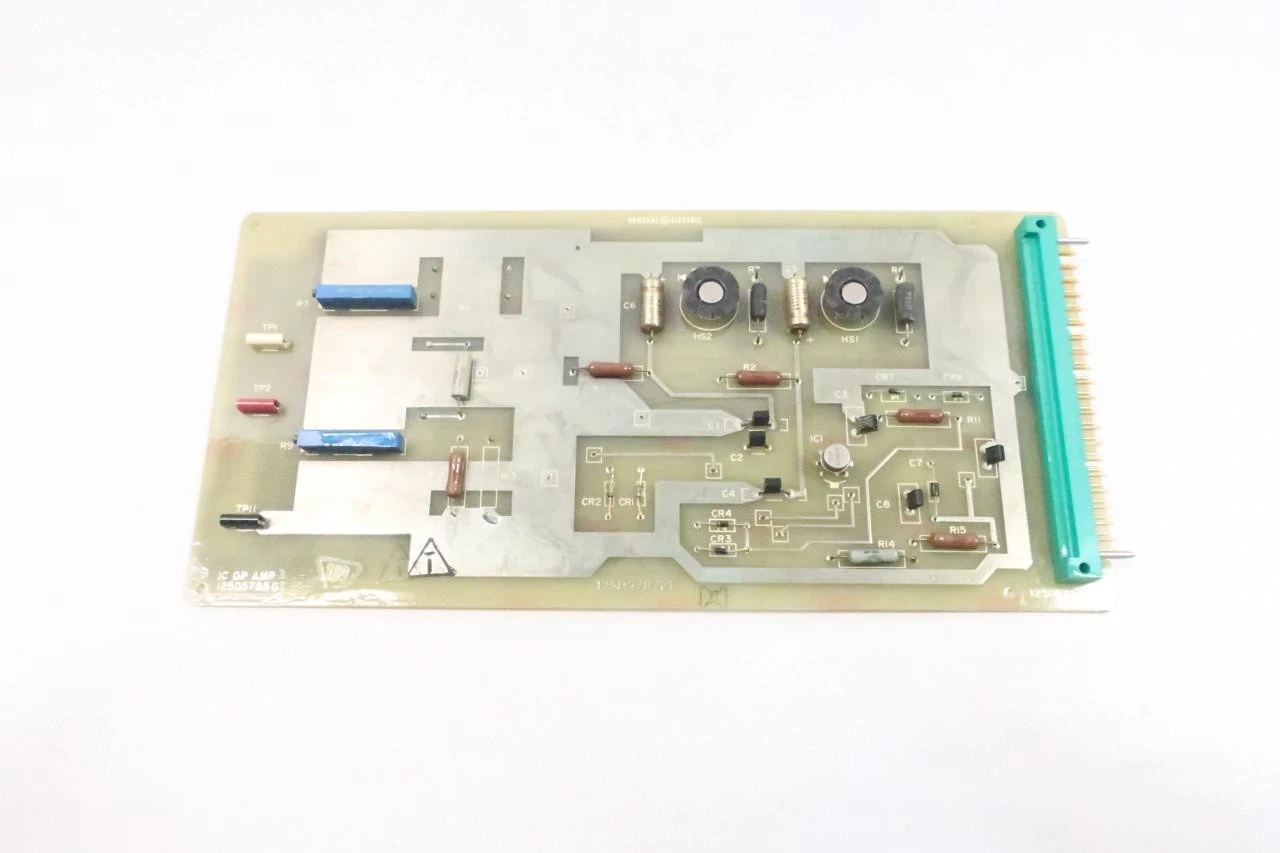

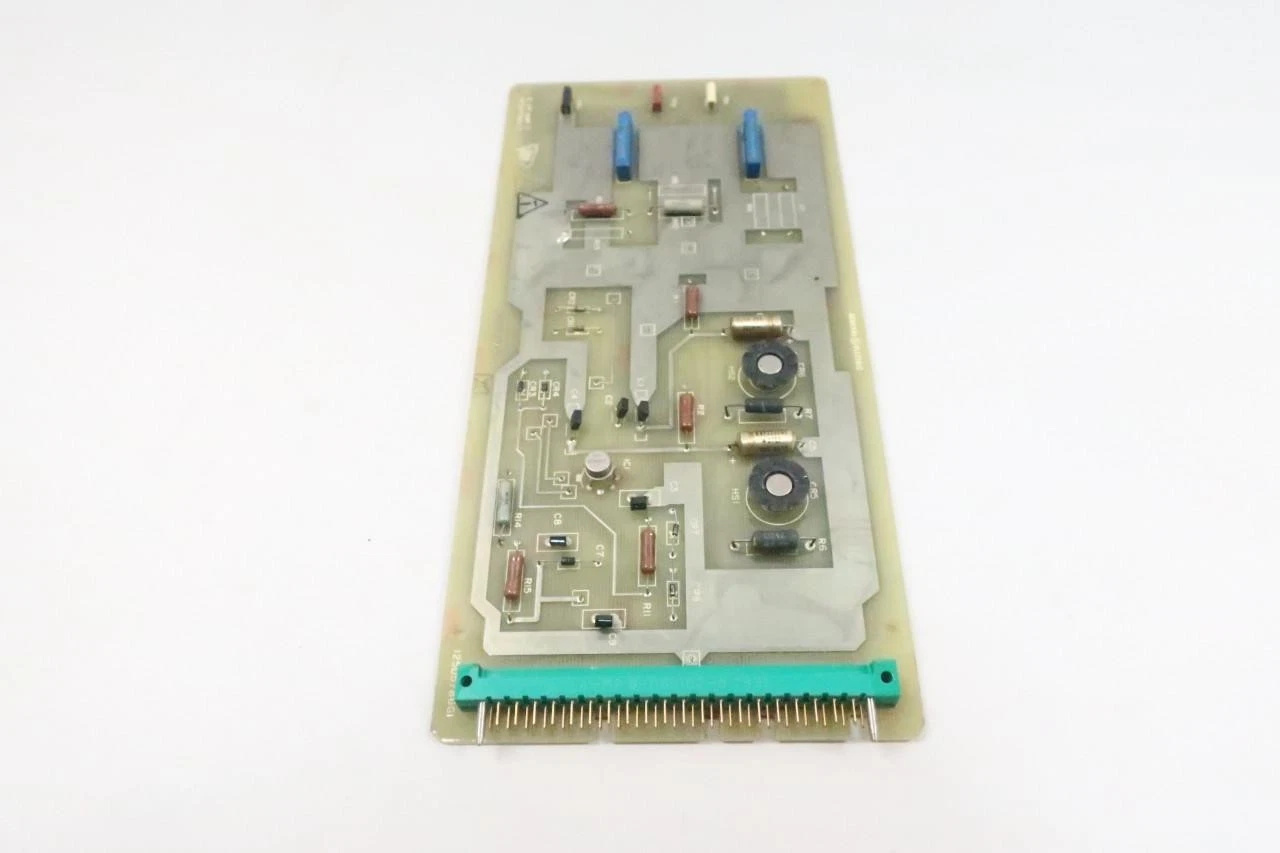

GE 125D5788G1 Operational Amplifier

GE 125D5788G1

1. Overview

- GE 125D5788G1 Product Positioning: A high-reliability operational amplifier circuit board for industrial automation, instrumentation, communication equipment, and other fields.

- Core Functions: Provides power supply, bias, input/output coupling, and protection circuits required by operational amplifiers, ensuring stable operation of the amplifier over a wide temperature range.

- Technical Standards: Complies with international standards such as IPC-2221 (General Electronic Board Design) and IEC-60950 (Safety of Information Technology Equipment), and meets RoHS and REACH compliance requirements.

2. Main Specifications

| Specification | Typical Value / Description |

|---|---|

| Board Material | FR-4 (1.6 mm thickness) |

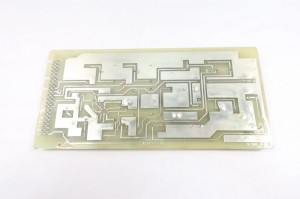

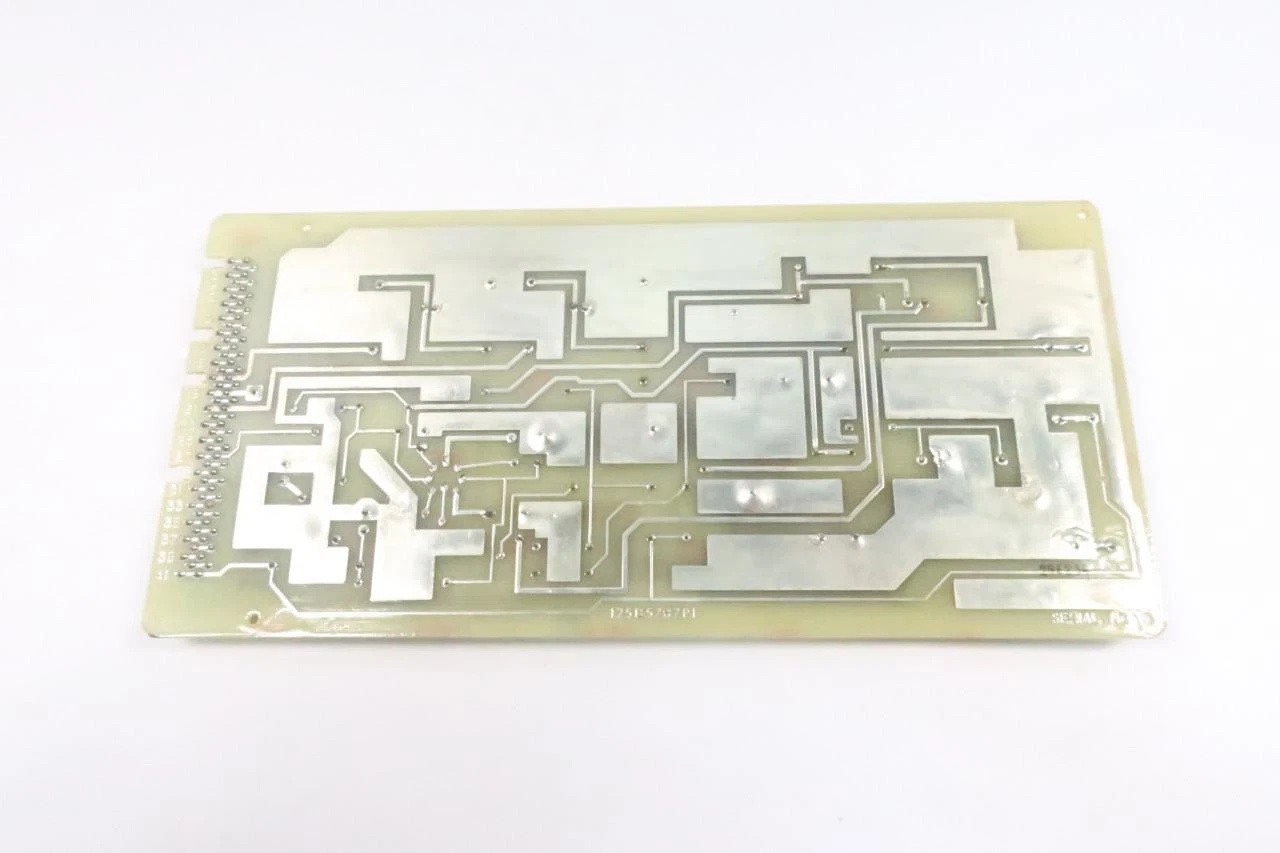

| Number of Layers | Double-layer (Top/Bottom) |

| Copper Thickness | 1 oz (approximately 35 μm) |

| Dimension | Approximately 120 mm × 80 mm (customizable according to customer requirements) |

| Operating Temperature | –40 °C ~ +85 °C |

| Power Supply Range | ±5 V ~ ±15 V (depending on the specifications of the mounted operational amplifier) |

| Withstand Voltage | 500 V (between boards) |

| Impedance Control | 50 Ω (for high-speed signal traces) |

| Surface Finish | ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling) |

| Packaging | Anti-static bag + impact-resistant carton |

3. Product Features

- High Reliability: Adopts military-grade welding technology, with solder joint strength ≥ 30 gf, and strong resistance to vibration and impact.

- Low-Noise Layout: Analog signal traces use layered isolation and complete ground planes to reduce parasitic capacitance and noise coupling.

- Multiple Protections: Built-in overvoltage, overcurrent, and ESD protection circuits to extend the service life of the operational amplifier.

- Easy Assembly: Provides standardized SMD/SMT pads, compatible with common surface-mount components, and supports automated placement production.

- Strong Compatibility: Can be used with multiple operational amplifiers in the GE series (such as 125D5787P1, 125D5786G1, etc.) to achieve rapid product iteration.

4. Structure and Composition

- Bottom Copper Foil: Forms a complete power plane and ground plane, providing low-impedance power distribution.

- Signal Layer: Arranges key components of the operational amplifier, such as input, output, bias resistors, and capacitors.

- Pad Area: Reserves standard 0603/0805/1206 SMD pads, compatible with multiple packages.

- Protection Components: Includes TVS diodes, thermistors (PTC), and fuse holders.

- Marking Layer: Silk-screen text indicates component positions, reference design numbers, batch numbers, and other information.

5. Application Fields

| Industry | Typical Applications |

|---|---|

| Industrial Automation | Sensor signal amplification, process control loops |

| Instrumentation | High-precision measurement amplification, data acquisition front-ends |

| Communication Equipment | Base station front-end amplification, RF preamplifiers |

| Medical Electronics | Biological signal (ECG, EEG) amplification |

| Automotive Electronics | On-board sensors, ADAS preamplification |

6. Installation and Maintenance

6.1 Installation Points

- Substrate Cleaning: Use a lint-free cloth or isopropyl alcohol to remove surface oil and dirt.

- Soldering Process: The recommended reflow soldering temperature profile is 150 °C ~ 250 °C, with a peak temperature not exceeding 250 °C to ensure complete solder joints.

- Positioning: Ensure the input/output direction of the operational amplifier is consistent with the PCB silk-screen marking to prevent phase errors.

- Anti-Static Measures: Wear an anti-static wristband during the assembly process to avoid ESD damage to sensitive components.

6.2 Maintenance Recommendations

- Regular Inspection: Check for cracks or bulges in solder joints, protection diodes, and capacitors every 6 months.

- Cooling Surface Cleaning: If heat sinks are mounted on the board, keep the surface of the heat sinks free of dust accumulation.

- Environment Monitoring: Use moisture-proof packaging or install protective covers when used in high-humidity or corrosive gas environments.

- Troubleshooting: In case of abnormal noise or output drift, first check power supply noise and ground integrity, then replace the operational amplifier or protection components one by one.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Why Should You Partner With Us?

- Comprehensive Spare Parts Stock: We maintain a global top-tier stock of industrial automation spare parts, encompassing all key control system components like PLCs, DCSs, drives, and HMIs. No matter the brand or model of your equipment, we guarantee fast and precise spare parts delivery to keep your operations running.

- Expert Technical Assistance: Our team is made up of seasoned engineers with profound expertise in diverse control systems. Whether you’re facing hardware malfunctions, software glitches, or need system upgrades, we can deliver expert technical guidance and tailored solutions.

- Tailored Service Offerings: In addition to standard spare parts supply, we also craft personalized solutions based on your unique requirements—such as equipment repair, system retrofitting, and specialized technical training.

- Worldwide Service Network: We’ve built a robust service network across the globe, ensuring that customers around the world receive prompt and efficient support whenever they need it.

- Going Beyond Basic Delivery: Whether it’s hard-to-find obsolete spare parts, service quality, or delivery speed, we consistently aim to provide services that go above and beyond your expectations.

- Commitment to Excellent Service: The concept of excellent service is embedded in every part of our work, as we strive to maximize value for each of our customers.

Write your message here and send it to us