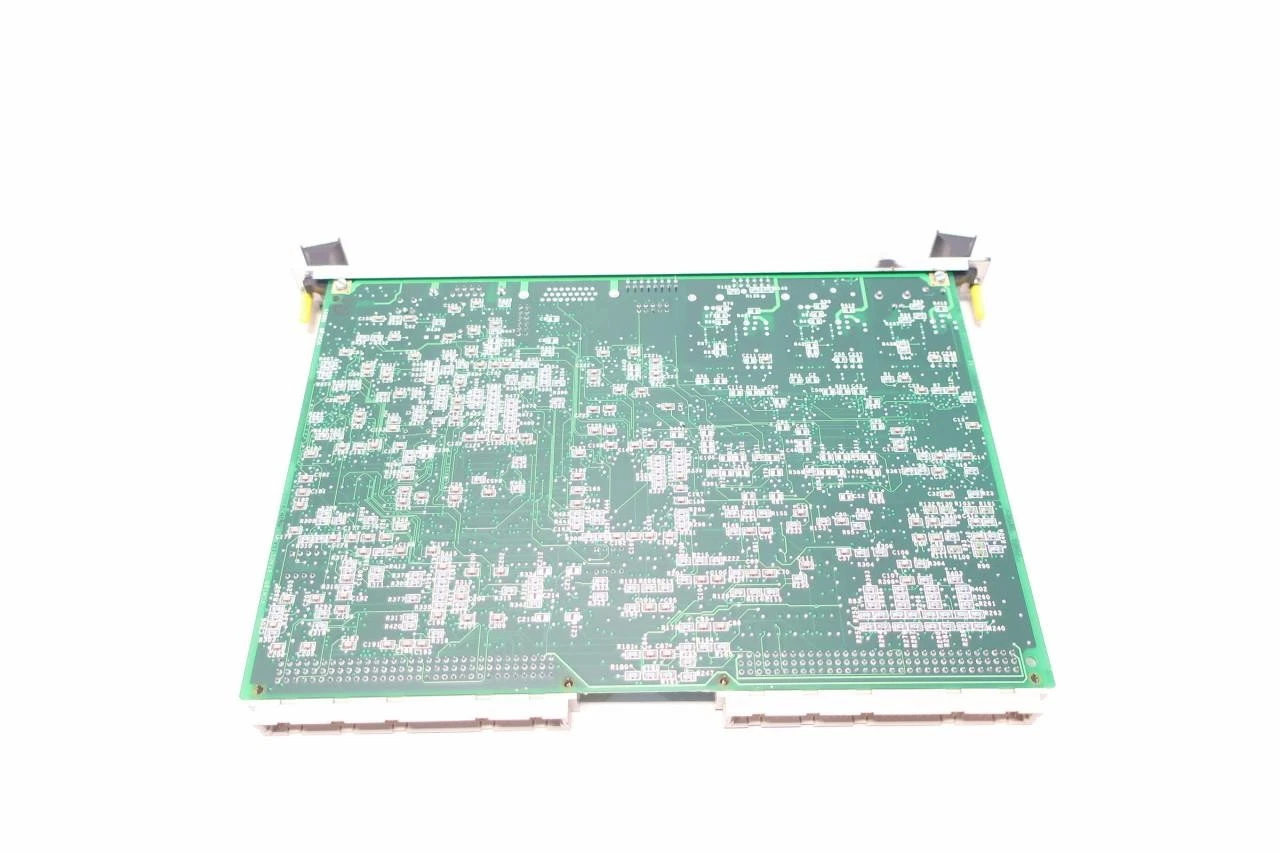

GE DS200LDCCH1ARA LAN Communication Board

GE DS200LDCCH1ARA

GE DS200LDCCH1ARA is a Drive Control/LAN Communication Board (LDCC) in the General Electric (GE) Mark Ⅴ series. It is specifically designed to provide core driving, I/O control, and local area network (LAN) communication functions for DIRECTO-MATIC 2000 series drives and exciters. The board integrates multiple microprocessors, enabling simultaneous handling of drive, motor, auxiliary motor, and LAN control tasks. It is also equipped with programmable memory, a display screen, and an optional handheld keyboard, facilitating on-site configuration and diagnosis.

Main Technical Specifications

- Part Number: DS200LDCCH1ARA

- Number of Microprocessors: 4 (for drive, motor, auxiliary motor, and LAN)

- Operating Voltage: 24 V DC (some documents indicate it can accept 90-125 V DC input)

- Operating Temperature Range: -40 °C ~ +70 °C (some models can reach +85 °C)

- Dimensions: Approximately 45 mm × 125 mm × 115 mm; Weight: Approximately 1.3 kg

- Protection Class: IP65 (dustproof and waterproof)

- Communication Interfaces: Ethernet LAN, RS-232/RS-485 (depending on specific configurations)

- Power Supply: Approximately 480 W; Efficiency: > 90%

Product Features

- Multi-processor Architecture: Enables parallel control of drive, motor, auxiliary motor, and network, improving response speed and reliability.

- Modular Design: Allows flexible installation in control cabinets or racks, supports multiple input voltages, and adapts to different on-site environments.

- Built-in Diagnostics and Human-Machine Interface (HMI): Equipped with a display screen and an optional handheld keyboard, enabling on-site parameter debugging, fault diagnosis, and software updates directly.

- High Reliability: Adopts industrial-grade components, has an IP65 protection class, and a wide operating temperature range, making it suitable for harsh industrial sites.

- LAN Communication Capability: Supports LAN data exchange, facilitating integration with upper-level systems or other control modules to achieve centralized monitoring and remote maintenance.

Structure and Composition

- Main Board: Integrates four microprocessors, memory (EEPROM/Flash), and power management circuits.

- I/O Interface Area: Provides digital, analog, and communication ports (Ethernet, serial ports).

- Display/Operation Unit: Includes an LCD/LED display screen and an optional handheld keyboard for on-site parameter input and status display.

- Heat Dissipation and Protection Structure: Features a metal shell combined with heat sinks to meet the IP65 protection requirements.

Typical Application Fields

- Industrial Automation: Used for precise control of large motor drive systems, such as conveyors, cranes, fans, and pumps.

- Energy and Power Generation: Provides reliable driving and monitoring in gas turbine and steam turbine drive systems.

- Oil, Gas, and Chemical Industry: Controls compressors, pump stations, and other key drive equipment.

- Power Systems: Serves as the core control module of power distribution cabinets or frequency converters to achieve efficient power conversion and protection.

Installation and Maintenance Points

- Installation Location: It is recommended to install it in a well-ventilated control cabinet or rack, and ensure electrical compatibility with other modules.

- Power Connection: Confirm that the power supply voltage meets the specifications (24 V DC or 90-125 V DC), and use cables that comply with IEC standards.

- Wiring and Interfaces: Correctly connect I/O, LAN, and motor/drive according to the wiring diagram to avoid signal interference.

- Initial Commissioning: Use the handheld keyboard provided with the board or connect a laptop via serial/Ethernet to load the factory configuration and modify parameters according to on-site requirements.

- Regular Inspection: Check the power supply, interfaces, and heat sinks every 6-12 months for looseness, corrosion, or dust accumulation; clean or replace aging components if necessary.

- Fault Diagnosis: Use the error codes on the on-board display screen or read the diagnostic logs via LAN to quickly locate the root cause of faults.

- Spare Parts and Warranty: Common spare parts include power modules, communication interface cards, and heat sinks; most suppliers provide a 12-36 month warranty service.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our Company: Product Range & Service Pledges

Our Service Pledges to Customers

- Pledge 1: We are committed to delivering products with consistent quality and exceptional after – sales support. While upholding strict quality standards, we strive to offer competitive and reasonable pricing to maximize customer value.

- Pledge 2: All products are sourced or procured in compliance with national or industry standards, ensuring they meet the required performance criteria. When used correctly, our products will have a service life comparable to or exceeding that of other similar products on the market. We also provide professional guidance to help customers select the most suitable product types and specifications based on their specific requirements.

- Pledge 3: (Note: The original content for Pledge 3 was not provided. To ensure the completeness of our service commitments, we recommend supplementing details such as technical consultation, customization support, or post – purchase training here.)

- Pledge 4: We prioritize on – time delivery. Under normal circumstances, customers can expect to receive their orders within 6 working days. For special cases (e.g., urgent orders, custom parts), we will work with customers to negotiate a flexible delivery timeline that aligns with their needs.

- Pledge 5: Since all products are manufactured by original overseas factories, after – sales service is provided directly by these manufacturers. The standard warranty period typically ranges from 6 months to 1 year, with specific terms subject to the original manufacturer’s policies. If a product experiences quality issues, and both parties confirm the problem stems from the manufacturer’s defects, we will facilitate the return of the product to the original factory for repair or arrange alternative solutions (e.g., replacement) as needed.

About Our Company