Welcome to our websites!

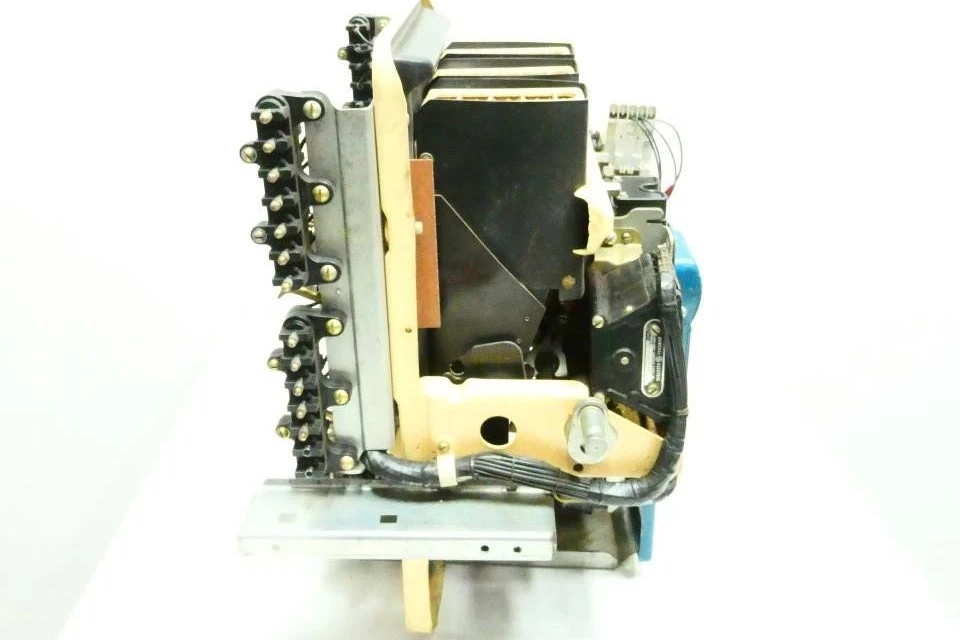

GE Akf-2-25 Air Circuit Breaker

GE Akf-2-25

GE AKF‑2‑25 is a low-voltage molded case circuit breaker (MCCB) manufactured by General Electric (GE), with a rated current/voltage of 600 A and 600 V. It is widely used for primary and branch circuit protection in power distribution systems, power plants, and large-scale industrial facilities.

It adopts a bolt-in structure, equipped with a reliable low-voltage undervoltage trip device and an adjustable thermal-magnetic trip unit. This enables it to quickly cut off the circuit under fault conditions such as overload, short circuit, and undervoltage, ensuring the safe operation of the system.

Key Technical Parameters

- Rated Current: 600 A (400 A, 800 A, and other series are optional)

- Rated Voltage: 600 V AC (also applicable for 250 V DC)

- Rated Interrupting Capacity: ≥ 42 kA (depending on specific models)

- Tripping Characteristic: Thermal-magnetic type with adjustable instantaneous tripping current; equipped with an undervoltage trip device

- Structural Form: Bolt-in installation, compatible with standard power distribution cabinets or bus ducts

- Terminal Specification: G3/4 inch for input, G1/2 inch for output

- Dimensions: 281 mm in length, 130 mm in width, 104 mm in height (including mounting holes)

Product Features

- High Reliability: Adopts air arc-extinguishing technology, featuring strong breaking capacity and a long maintenance cycle.

- Modular Design: The bolt-in structure allows for quick replacement or upgrading in power distribution cabinets.

- Adjustable Tripping: The thermal-magnetic trip unit can be adjusted according to load characteristics to meet the needs of various working conditions.

- Undervoltage Protection: Built-in undervoltage trip device to prevent equipment malfunction caused by voltage drop.

- Compliance with International Standards: Conforms to low-voltage switchgear standards such as IEC 60947-2 and UL 489.

Structure and Composition

- Enclosure: Metal enclosure that provides mechanical strength and protection.

- Contact System: Main contacts and auxiliary contacts made of high-conductivity copper alloy.

- Arc Extinguisher Chamber: Air arc extinguisher chamber that cools and extinguishes arcs using high-speed air flow.

- Thermal-Magnetic Trip Unit: Adjustable thermal element and magnetic trip coil.

- Undervoltage Trip Device: Monitors voltage and triggers tripping when the voltage is below the set threshold.

- Terminals and Terminal Blocks: Provide reliable electrical connections.

Typical Application Fields

- Power Plant Distribution: Overload and short-circuit protection for primary and secondary distribution circuits.

- Large Industrial Plants: Protection for motors, transformers, and power distribution cabinets.

- Commercial Buildings: Main protection device for building power distribution systems.

- Power System Automation: Links with relay protection devices to realize remote monitoring and control.

Installation Key Points

- Model Selection Matching: Confirm that the rated current and rated voltage are consistent with system requirements.

- Bolt-in Installation: Use standard bolts to fix the circuit breaker in the power distribution cabinet or bus duct to ensure mechanical stability.

- Wiring: Follow the IEC 60947-1 wiring specifications to ensure correct phase sequence and secure wiring.

- Grounding: The enclosure must be reliably grounded to prevent leakage.

- Inspection and Commissioning: After installation, conduct calibration tests for low-voltage tripping and thermal-magnetic tripping to ensure the operating characteristics meet design requirements.

Maintenance Recommendations

- Regular Inspection: Check contact wear, bolt tightness, and the cleanliness of the arc extinguisher chamber every 6 to 12 months.

- Functional Testing: Perform functional tests on the undervoltage trip device and thermal-magnetic trip unit to verify the operating time and set values.

- Component Replacement: If contact ablation or spring looseness is found, replace the corresponding components in a timely manner to prevent fault expansion.

- Record Logging: Document the maintenance process to facilitate traceability and subsequent analysis.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our Company: Product Range & Service Pledges

As a professional supplier, our company focuses on providing 100% original imported spare parts for four key industrial systems—DCS, PLC, industrial robots, and large – scale servo systems. These parts are sourced from leading global brands, including FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Aen – Brady, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westinghouse, WOODWARD, Motorola, Rexroth, and SEW. Additionally, we specialize in procuring hard – to – find, out – of – production accessories to meet customers’ urgent or specialized needs.

Our Service Pledges to Customers

- Pledge 1: We are committed to delivering products with consistent quality and exceptional after – sales support. While upholding strict quality standards, we strive to offer competitive and reasonable pricing to maximize customer value.

- Pledge 2: All products are sourced or procured in compliance with national or industry standards, ensuring they meet the required performance criteria. When used correctly, our products will have a service life comparable to or exceeding that of other similar products on the market. We also provide professional guidance to help customers select the most suitable product types and specifications based on their specific requirements.

- Pledge 3: (Note: The original content for Pledge 3 was not provided. To ensure the completeness of our service commitments, we recommend supplementing details such as technical consultation, customization support, or post – purchase training here.)

- Pledge 4: We prioritize on – time delivery. Under normal circumstances, customers can expect to receive their orders within 6 working days. For special cases (e.g., urgent orders, custom parts), we will work with customers to negotiate a flexible delivery timeline that aligns with their needs.

- Pledge 5: Since all products are manufactured by original overseas factories, after – sales service is provided directly by these manufacturers. The standard warranty period typically ranges from 6 months to 1 year, with specific terms subject to the original manufacturer’s policies. If a product experiences quality issues, and both parties confirm the problem stems from the manufacturer’s defects, we will facilitate the return of the product to the original factory for repair or arrange alternative solutions (e.g., replacement) as needed.

About Our Company

Our company boasts strong technical capabilities, a comprehensive range of equipment, and advanced testing methods—all of which ensure our products are reliable and high – performing. Guided by the principle of “putting customers first,” we maintain strict delivery schedules, offer fair pricing, deliver top – quality products, and provide thorough after – sales service. Over the years, this commitment has enabled us to build long – term, trustworthy partnerships with numerous new and existing customers. Our products stand out for their reliable performance and unique advantages, earning us the trust and preference of clients across various industries.

Write your message here and send it to us