Welcome to our websites!

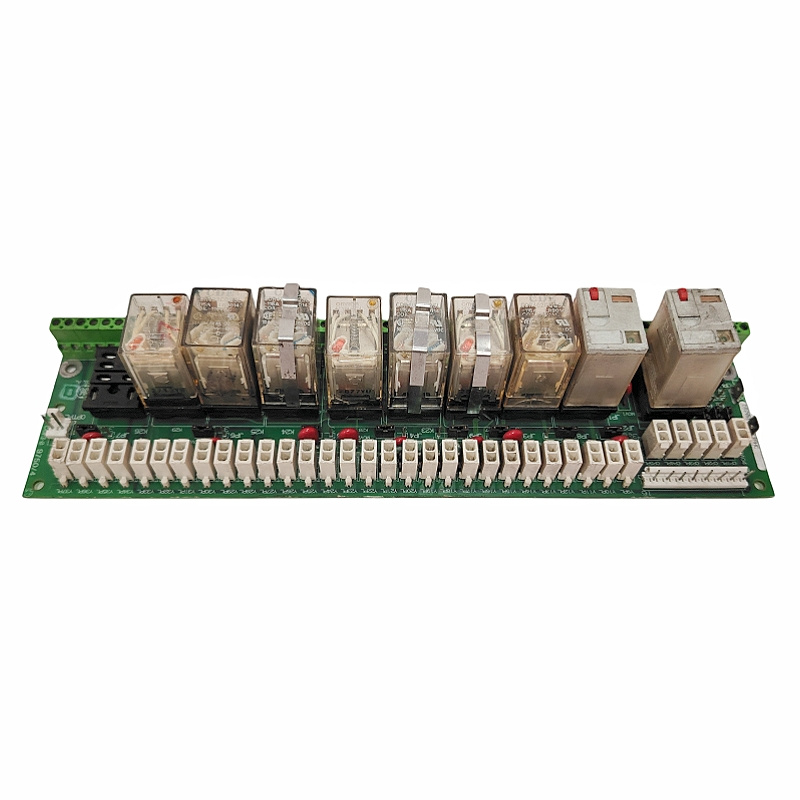

GE DS200RTBAG3AHC Relay Terminal Board

GE DS200RTBAG3AHC

1. General Description

The GE DS200RTBAG3AHC is a relay terminal board that is part of the GE Mark V series control system. It is primarily used to connect and manage various types of relays, enabling the control and protection of steam turbine systems. This module features high reliability and stability, is designed for long-term use in industrial environments, and supports system integration and expansion.

2. Parameters

- Model: DS200RTBAG3AHC

- Brand: GE (General Electric)

- Type: Relay terminal board/control card

- Rated voltage: Supports multiple voltage ranges, depending on application scenarios and configurations (e.g., 120V AC)

- Frequency: Supports 47-63Hz alternating current

- Power consumption: Relatively low, such as 2.6W

- Dimensions: Standard industrial size, e.g., 123×232mm (Note: There is a conflicting dimension mentioned as 100 x 50 x 25 mm; please refer to the official specifications for accuracy)

- Color: Standard industrial gray or customizable upon request

- Certification: CE and other international standard certifications

- Operating temperature range: -20°C to +60°C (Note: Another range of -40°C to +70°C is mentioned; please refer to the official specifications for accuracy)

- Protection class: IP20, suitable for installation in control cabinets

- Output voltage: 10-20 VAC

- Output current: 100 mA

- Weight: 0.5kg

3. Product Features

- Modular design: Facilitates installation, maintenance, and upgrades, improving the maintainability and scalability of the system.

- High reliability: Uses industrial-grade components, ensuring high reliability.

- High safety: Contains high energy; extra caution is required during use to avoid contact and prevent safety risks.

- Versatility: Integrates multiple input/output (I/O) interfaces, allowing users to configure circuits according to specific needs.

- Status indication function: Equipped with LED indicators to provide the operating status of each relay.

- Fault protection: Designed with functions to reduce the risk of electrical faults.

- Compatibility: Specifically designed for the GE Mark V system, ensuring seamless integration with other Mark V components.

4. Structure and Composition

- Relay configuration: Contains 10 relays, which can be directly driven by pilot relays or remotely controlled by users.

- Number of terminals: There are 52 terminals on the board, mainly used for input/output (I/O) purposes.

- Plug connectors: Equipped with two plug connectors, namely the positive power connector CPH and the negative power connector CPN, providing pluggable circuit control power.

- Material: The printed circuit board usually uses high-quality insulating materials to ensure reliability and durability.

- Structure: Modular design for easy installation and maintenance.

5. Application Fields

- Power industry: Turbine control systems, power plant automation systems, etc.

- Industrial automation: Industrial process control systems, machine automation, etc.

- Petrochemical industry: Petrochemical process control systems, etc.

- Water treatment: Used in water treatment plants to monitor and control the operation status of water quality treatment equipment.

- Manufacturing: As a key control component in automated production lines, ensuring the stability and efficiency of the production process.

- Wind power generation: Used for the control and protection of wind power generation systems.

- Petroleum energy: Realizing remote monitoring and control in the process of oil and gas extraction, processing, and transportation.

6. Installation and Maintenance

Installation:

- The module is usually installed in the drive cabinet, via DIN rail or panel mounting.

- Ensure all power supplies are disconnected before installation to avoid electric shock risks.

- Use the control panel to stop the motor and shut down the drive according to standard procedures.

- Locate the power supply providing three-phase current and pull out the fuses.

Maintenance:

- Regularly check the connection of connectors and terminals to ensure there is no looseness or corrosion.

- Check the working status of relays to ensure they are operating normally.

- Clean the surface of the module to prevent dust and dirt from affecting performance.

- Follow the manufacturer’s maintenance guidelines to ensure long-term stable operation of the equipment.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Xiamen Xingruijia

Xiamen Xingruijia focuses on four major system fields: DCS, PLC, robots, and large-scale servo systems.

Our main products include various modules/cards, controllers, touch screens, and servo drives.

Company Advantages

- Supply of imported original genuine products, professional discontinued accessories

- Fast delivery with accurate lead time

- First-hand sources of goods

- In-stock inventory exceeding 100 million yuan

Frequently Asked Questions

Q: Do you provide a warranty for the products?

A: Yes, we provide a warranty for all goods from us.

Q: Can you provide technical support?

A: We have been in this field for 15 years. If you have any problems, please contact us, and we will provide engineers’ suggestions to help you solve them.

Q: Do you have inventory or just do transactions?

A: We have a large warehouse with a large number of goods, so we can ensure fast delivery.

Q: Are your products new and original?

A: Yes, they are new and original.

Write your message here and send it to us