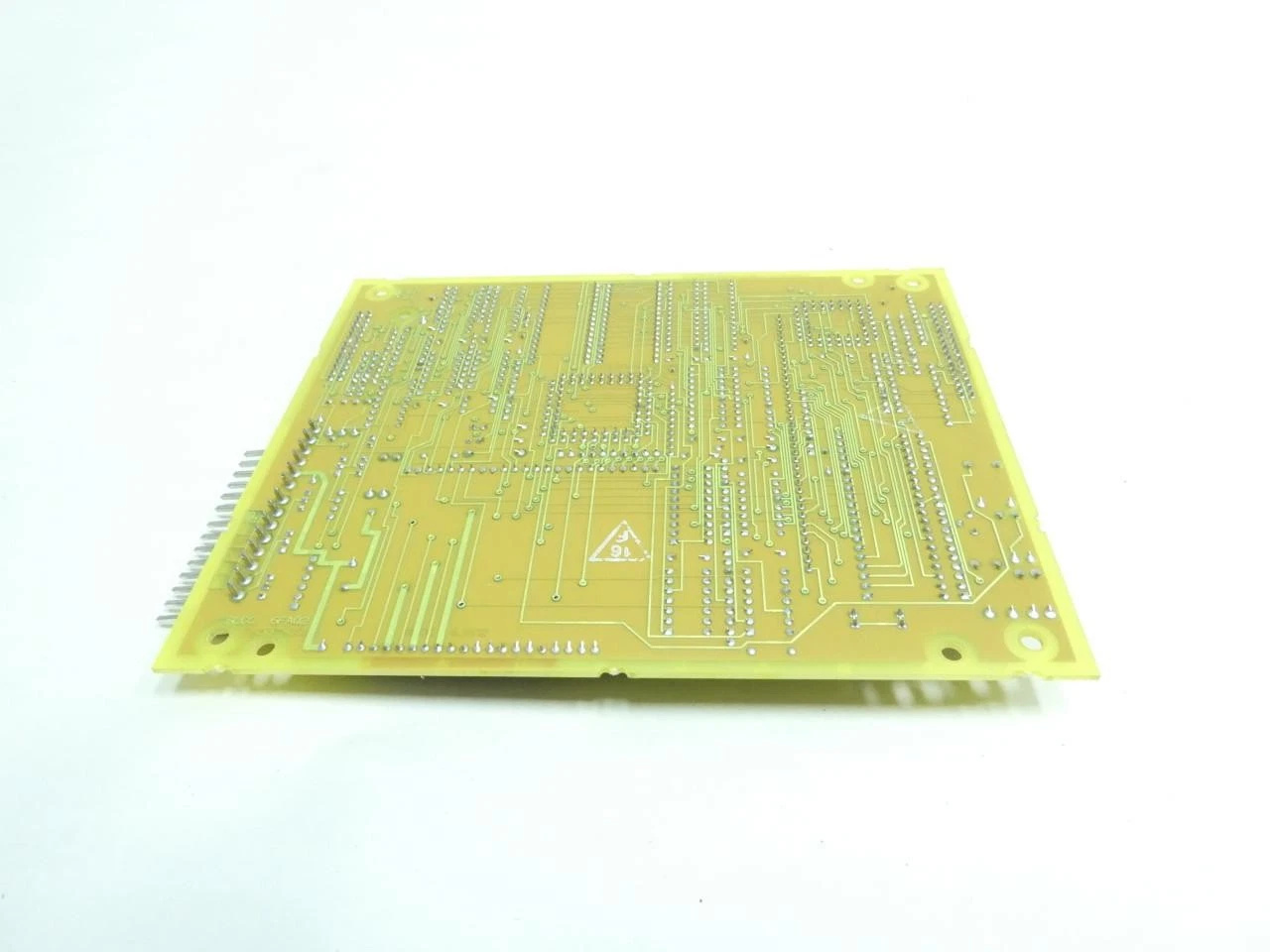

GE DS200SLCCG3ACC Communication Board

GE DS200SLCCG3ACC

GE DS200SLCCG3ACC is a LAN (Local Area Network) communication board developed by General Electric (GE) for the Mark V series control systems. It is specifically designed to replace old driver boards. The board enables reliable Ethernet signal transmission between various GE drives and exciters, allowing upper computers to exchange data with host drives via LAN. It offers two circuit options: isolated and non-isolated. All signals are processed by an internally integrated LAN Control Processor (LCP), with programs stored on two replaceable EPROM cards. It supports high-speed data exchange with host drives through dual-port RAM.

Main Technical Specifications

- Category: System Logic Control Card

- Compatible Systems: GE Mark V control system (including Mark VIe)

- Supply Voltage: 24 V DC (120~240 V AC supported by some models)

- Communication Interface: 10/100 Mbps Ethernet (RJ-45)

- Storage: Two replaceable EPROM cards, supporting on-site upgrades

- Signal Isolation: Isolated and non-isolated versions available to meet different on-site safety requirements

- Dimensions: Compliant with GE standard module dimensions, directly mountable into corresponding cabinets or drive bases

Product Features

- Plug-and-Play: Modular design ensures easy installation, supports hot-swapping, and facilitates quick on-site replacement.

- High Reliability: Adopts industrial-grade components, featuring electromagnetic interference (EMI) resistance and a wide operating temperature range (-20 °C~+60 °C).

- Dual Storage Redundancy: Two EPROM cards achieve program redundancy, preventing system failure caused by single-point faults.

- Diagnostic Function: Equipped with a programming keyboard for direct access to system diagnostic information, enabling easy fault location.

- Strong Compatibility: Compatible with various GE drives, exciters, and Mark VIe series controllers, suitable for a wide range of industrial automation scenarios.

Structure and Composition

- LAN Control Processor (LCP): Responsible for Ethernet protocol stack and data forwarding.

- Dual-Port RAM: Enables high-speed bidirectional data exchange with host drives.

- Power Supply Module: Provides 24 V DC stabilized voltage, with built-in overvoltage and overcurrent protection.

- Isolated/Non-Isolated Circuit Board: Optional based on on-site requirements to ensure signal safety.

- EPROM Storage Slots: Two replaceable EPROM cards for storing firmware and user programs.

- Programming Keyboard Interface: Used for on-site debugging and system diagnosis.

- Connectors: RJ-45 Ethernet port, system backplane interface, and power terminals.

Typical Application Fields

- Power plant (gas turbine, steam turbine) control systems

- Petrochemical process automation

- Heavy industry production lines (e.g., papermaking, steel)

- Large pump station and compressor drive systems

- Any on-site scenario requiring integration of GE Mark V/VIe controllers into enterprise Ethernet

Installation and Maintenance Guidelines

- Pre-Installation Preparation: Read the technical manual to confirm matching of power supply, voltage, and backplane interface; check if the anti-static plastic bag in the package is intact.

- Fixing Method: Use standard screws to fix the board in the corresponding slot of the cabinet or drive base, ensuring a secure backplane connection.

- Wiring: Connect the power supply first, then the Ethernet. Avoid hot-plugging during power-on to prevent electrical shock.

- Firmware Upgrade: Write the new firmware into the EPROM card and insert it into the slot; the system will automatically switch to the latest version. It is recommended to keep the original card for rollback.

- Diagnosis and Debugging: Use the accompanying programming keyboard or GE software on a PC to read diagnostic codes, check network status, and quickly locate faults.

- Regular Inspection: Inspect the tightness of connectors, cleanliness of heat sinks, and physical integrity of EPROM cards every six months.

- Replacement Strategy: If communication interruption, diagnostic codes indicating hardware faults, or EPROM card read/write errors occur, replace the EPROM card first. If the problem persists, replace the entire board.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our Product Commitments

Ordering Process