GE IS220PVIBH1AL Special Module

GE IS220PVIBH1AL

The IS220PVIBH1AL is a dedicated module developed by General Electric (GE) for its Mark Ⅵ series control systems, particularly the Mark Ⅵe. It is mainly used for vibration monitoring and gas turbine control. The module can collect mechanical vibration or gas turbine operating parameters in real time, and convert analog signals into digital data. This data is then used by the upper-level system for trend analysis, alarming, and fault diagnosis, thereby improving equipment reliability and operational safety.

Key Technical Specifications

- Operating Voltage: 24 V DC

- Input Signals: Analog voltage (typically ±10 V) or output voltage from vibration sensors

- Number of Channels: Multi-channel design, supporting simultaneous connection of multiple vibration or analog sensors

- Sampling Rate: High-speed sampling, meeting real-time monitoring requirements

- Operating Temperature Range: -25 ℃ ~ +65 ℃

- Dimensions/Form Factor: Standard rack-mounted module, approximately 53 mm in width, 125 mm in height, 260 mm in depth, and 0.7 kg in weight

- Interface Type: VME bus or Ethernet

- Certifications: Industrial safety certifications such as UL and CE

Product Features

- High-Precision Vibration Acquisition: Accurately captures mechanical vibration signals, supporting trend monitoring and spectrum analysis.

- Multi-Functional Alarming: Automatically triggers alarms when vibration or key operating parameters exceed set thresholds, helping to prevent faults in advance.

- Diagnosis and Protection: Built-in fault diagnosis algorithms, which can work with gas turbine card functions to automatically cut off fuel supply or shut down the machine in case of abnormalities, providing equipment protection.

- Modular Design: Compact structure with easy plug-and-play functionality, facilitating quick on-site replacement and expansion.

- Industrial-Grade Reliability: Suitable for harsh environments such as high temperatures and strong electromagnetic interference, with multiple protections including overcurrent, overvoltage, and undervoltage.

- Strong Compatibility: Seamlessly integrates with GE Mark Ⅵ/Mark Ⅵe systems, supporting dual-channel communication via VME bus and Ethernet.

Structure and Composition

- Front Panel: Indicators, power interface, and Ethernet/VME interface ports.

- Internal Circuitry: High-precision analog-to-digital conversion chips, signal conditioning amplifiers, and protection circuits (for overvoltage, overcurrent, and undervoltage).

- Heat Dissipation Structure: Metal heat sinks or fans (depending on the specific model), ensuring stable operation in high-temperature environments.

- Connection Terminals: Multi-channel analog input terminals (screw-type or plug-in type), facilitating connection to vibration sensors or other analog sensors.

Typical Application Areas

- Gas Turbine/Steam Turbine Monitoring: Real-time monitoring of key parameters such as rotor vibration, temperature, and pressure, providing overspeed protection and synchronization checks.

- Industrial Vibration Monitoring: Used for health monitoring and preventive maintenance of large rotating machinery (e.g., compressors, pumps, generators).

- Process Control Systems: Serves as an analog input module to receive signals from on-site instruments such as flowmeters and pressure transmitters.

- Power Plants and Petrochemical Industry: Provides key parameter acquisition and alarming in scenarios with high reliability requirements, such as power stations, oil refineries, and natural gas compression stations.

Installation and Maintenance Guidelines

- Power Supply and Grounding: Ensure stable 24 V DC power supply, and use grounding methods that comply with industrial standards to suppress electromagnetic interference.

- Mechanical Fixing: Install using standard racks or DIN rails to ensure the module is securely fixed and shockproof.

- Signal Wiring: Select appropriate analog input terminals based on the sensor type, keep cables shielded, and avoid noise introduction over long distances.

- Communication Configuration: In VME bus or Ethernet environments, set the node address and baud rate according to the system manual to ensure normal communication with the upper-level DCS/PLC.

- Regular Inspection: Inspect the power supply, interfaces, and heat dissipation devices every 6-12 months, remove dust, and check the status of indicators.

- Firmware Upgrade: If a new version of firmware is released, upgrade it in accordance with GE’s official guidelines to obtain the latest functions and security patches.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

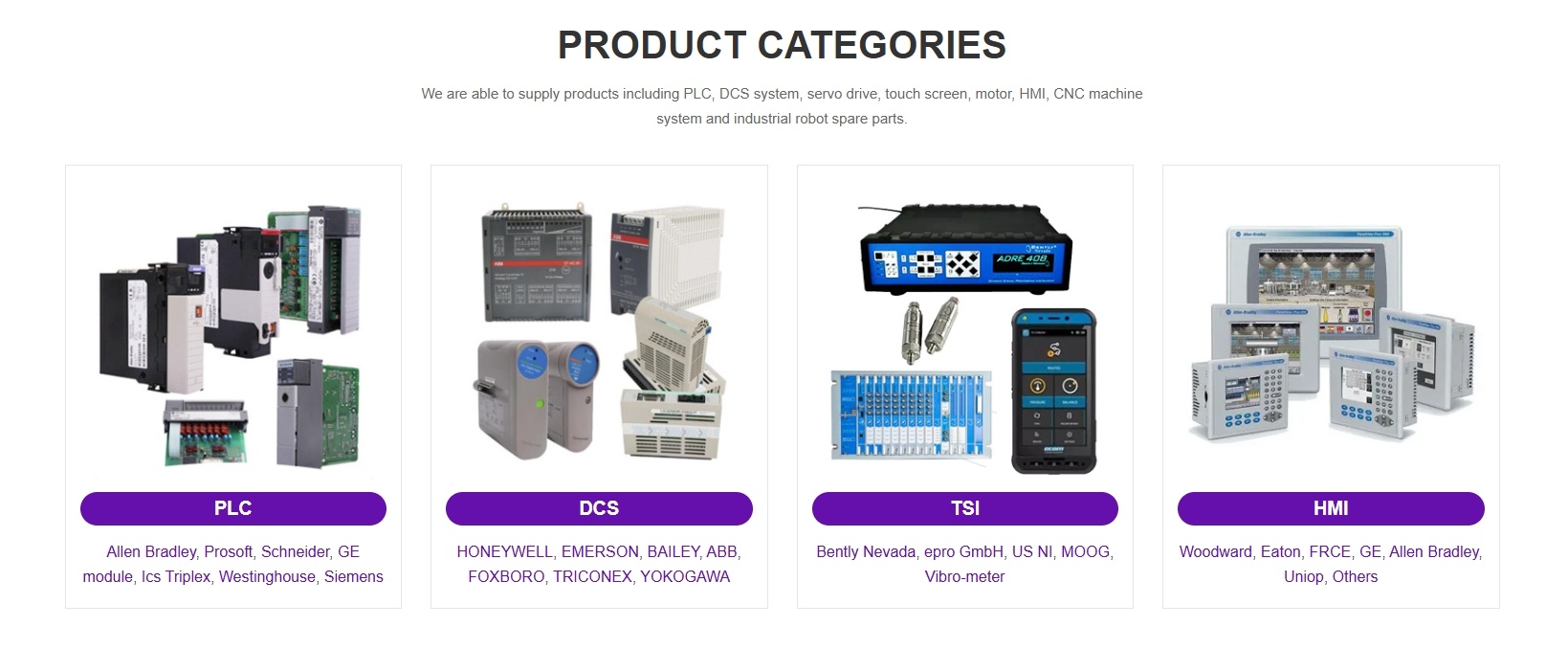

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Xiamen Xingruijia Import and Export Co., Ltd.

About Logistics

- Geographical Edge: As a company based in Xiamen—a key port city—we leverage well-developed sea, air, and land transport networks to enable swift domestic and international cargo movement, effectively cutting down delivery cycles.

- Global Logistics Connections: Through partnerships with world-renowned logistics providers, we offer a variety of transportation options, including ocean freight and air cargo services, guaranteeing that goods reach destinations worldwide safely and efficiently.

- Customizable Transportation Solutions: Tailored to meet specific customer requirements, we provide services such as door-to-door delivery, less than container load (LCL) shipping, and full container load (FCL) shipping. These solutions help clients lower operational costs and enhance overall efficiency.

- Real-Time Cargo Tracking: We provide real-time tracking functionality for shipped goods, allowing customers to monitor the transportation status at any moment and ensuring that deliveries arrive as scheduled.

- Professional Customs Clearance Services: Our team offers fast customs declaration procedures and professional tariff consultation, facilitating smooth customs clearance for international shipments and minimizing potential delays.

- Premium Packaging Standards: We use internationally compliant packaging materials to ensure that goods remain intact throughout the transportation process. Additionally, we offer customized packaging solutions to meet unique customer needs.