Welcome to our websites!

GE V4562076-0200 Check Valve

GE V4562076-0200

1. Overview

GE V4562076-0200 is part of the imported wafer-type check valve series. It adopts a wafer-type structure to achieve one-way fluid control and is widely used in pipeline systems for high-pressure or high-temperature working conditions in industries such as petroleum, chemical engineering, metallurgy, and electric power.

2. Specifications

- Connection Type: Flange connection

- Operating Pressure: PN 16 ~ PN 25

- Operating Temperature: -30 °C ~ +250 °C

- Material: The valve body is usually made of carbon steel, alloy steel, or stainless steel; the sealing surface is made of cemented carbide or polytetrafluoroethylene (PTFE)

- Fluid Medium: Water, steam, oil products, acids, alkalis, etc.

3. Product Features

- Wafer-type structure enables quick assembly and disassembly without welding, facilitating on-site maintenance.

- Reliable sealing with a double-seal design to prevent leakage.

- Compact structure and relatively light weight, suitable for installation environments with limited space.

- Optional electric or pneumatic actuators for automated control.

- Certified by quality management systems such as ISO 9001 and CE, complying with international standards.

4. Structure and Components

- Valve body (with flange connection)

- Wafer-type valve cover and valve seat

- Sealing elements (cemented carbide or PTFE)

- Handwheel or actuator (electric/pneumatic)

- Accessories such as flange bolts and gaskets

5. Application Fields

- Petroleum and Chemical Industry: Anti-reverse flow protection for crude oil, finished oil, and natural gas transportation systems.

- Electric Power Industry: Check valves for boiler feed water and steam systems.

- Metallurgy and Iron & Steel Industry: Flow direction control of high-temperature and high-pressure media.

- Food and Beverage Industry: Check valves that meet hygiene requirements.

- Other industrial pipelines requiring anti-reverse flow functionality.

6. Installation and Maintenance

Installation

- First, check whether the valve body, valve cover, and sealing surface are in good condition.

- Use compliant flange bolts and gaskets, and tighten them evenly according to the specified torque.

- Confirm that the valve direction mark is consistent with the pipeline flow direction.

- If an actuator is used, complete the electrical or pneumatic wiring in accordance with the manufacturer’s wiring diagram.

Commissioning

- Conduct a closure test before fluid flow to check for sealing leakage.

- If an automatic actuator is used, calibrate the stroke and response time.

Maintenance

- Regularly inspect the valve body appearance and bolt tightness.

- Replace the sealing elements every 6 to 12 months (the interval can be appropriately extended based on the corrosion degree of the medium).

- Lubricate the electric/pneumatic actuator and inspect its circuits.

- In case of leakage or jamming, first disassemble the valve cover to check the wear of the sealing surface, and replace the valve body or valve cover if necessary.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

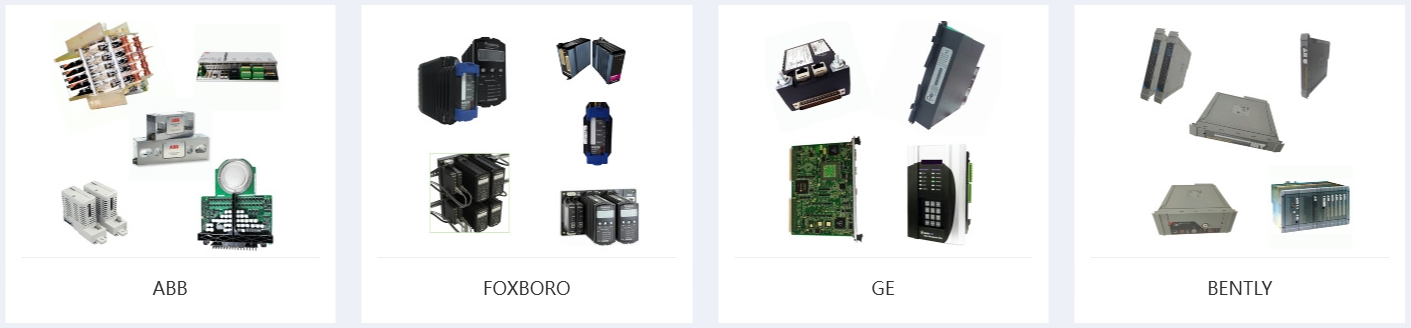

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Your Reliable Partner for Customized Automation Solutions

As a seasoned expert dedicated to automation technology, we have established ourselves as a trustworthy ally for businesses seeking tailored automation support. Leveraging decades of focused experience in the automation sector, we deliver comprehensive product portfolios and professional services, spanning core components like PLCs, DCS systems, and variable frequency drives (VFDs). Whether you need to optimize complex process control in the petrochemical industry or implement energy-saving solutions for motors in the power sector, our team excels at crafting solutions that align perfectly with your unique operational needs. Our products are recognized for consistent performance and exceptional reliability, all of which have been validated through rigorous international quality certifications.

Why Partnering with Us Adds Value to Your Business

- Superior Quality Assurance: Every product and solution undergoes strict quality checks to meet industry-leading standards, minimizing operational risks for your business.

- On-Time Delivery Commitment: We prioritize efficient supply chain management to ensure your orders are delivered promptly, avoiding delays in your production or project timelines.

- Extensive Range of Branded Components: We stock and supply a wide selection of parts from well-known, reputable brands, guaranteeing compatibility and durability.

- Expert Team & Advanced Testing Facilities: Our team of seasoned professionals, combined with state-of-the-art testing equipment, ensures every solution is fully validated before deployment.

- Ample Inventory Reserves: We maintain large inventory levels to meet your urgent needs, reducing lead times and keeping your operations running smoothly.

- 100% Genuine New Products: We strictly provide original, brand-new items—no refurbished or counterfeit products—ensuring the highest quality and long-term performance.

Write your message here and send it to us