HIMA F8650 Central Processing Unit

HIMA F8650

1. Overview

2. Technical Specifications

Processor & Performance

- CPU Type: Adopts dual-processor redundancy design. Some models (e.g., F8650) use Intel 386EX microprocessors operating in clock synchronization.

- Operating Frequency: Approximately 25 MHz (slight differences between specific models).

- Memory: Equipped with Flash-EPROM (1 MB + 512 KB) and SRAM (256 KB) for program storage and data processing.

________________________________________________________________________________________________________

Interface & Communication

- Display: 4-digit matrix display for showing system status, fault codes, and other information.

- Communication Interface: Mainly communicates via RS485 serial interface.

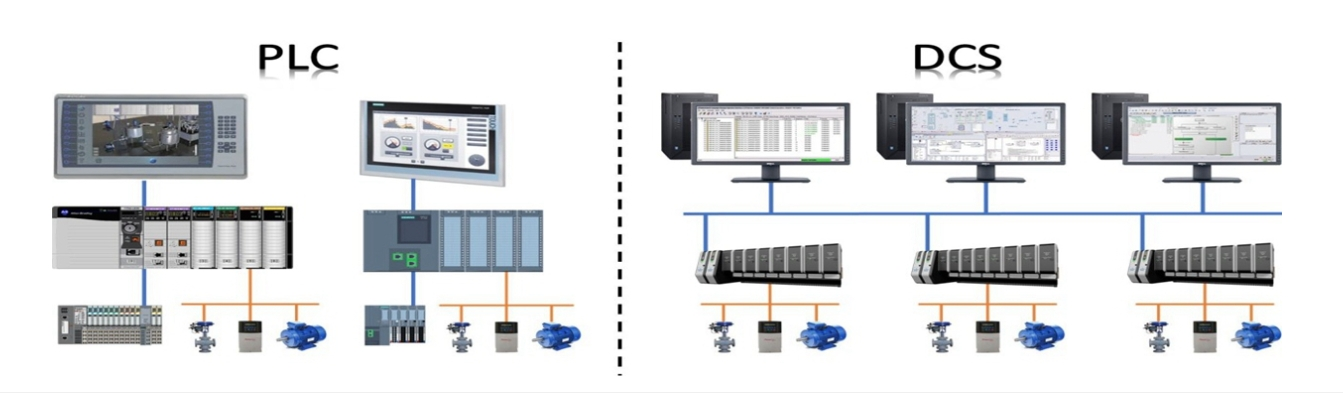

- Programming Language: Supports IEC 61131-3 standard programming languages (e.g., Ladder Logic, Structured Text).

________________________________________________________________________________________________________

Environmental Adaptability

- Temperature Range: Operating temperature typically -40°C to 70°C; storage temperature -40°C to 85°C.

- Protection Class: IP67.

- Power Supply: 24V DC with redundant power supply design.

________________________________________________________________________________________________________

3. Key Features

4. Structure and Composition

Core Hardware

- Dual CPU Motherboard: Integrates two independent CPU motherboards that are mirror images of each other.

- Memory Modules: Flash-EPROM and SRAM for storing programs and real-time data.

Peripheral Components

- Communication Card: Responsible for data exchange with upper computers or other controllers.

- Display Panel: User interface for showing real-time status.

- Power Supply Module: Provides stable 24V DC power input with redundant design.

________________________________________________________________________________________________________

5. Applications

- Chemical & Oil & Gas: Serves as the core control unit for Emergency Shutdown Systems (ESD) or Fire & Gas Detection Systems (F&G).

- Energy & Power Generation: Used in Safety Instrumented Systems (SIS) of nuclear power plants or thermal power plants, such as High Integrity Pressure Protection Systems (HIPPS).

- Transportation: Applied in the safety layer of rail transit signal systems or train control systems.

- Process Industry: Burner Management Systems (BMS), turbine control, etc.

________________________________________________________________________________________________________

6. Installation & Maintenance

Installation Method

- DIN Rail Mounting: The F8650 adopts a standard DIN rail design, facilitating installation and replacement in cabinets.

- Backplane Connection: Connects to I/O modules or power supply modules via a backplane.

Maintenance Requirements

- Regular Inspection: Use the display and remote diagnostic tools to regularly check the system’s health status, focusing on fault indicators and error codes.

- Redundancy Testing: Regular redundancy function tests are required to ensure both channels can work normally.

- Firmware Update: Perform firmware or software upgrades under official guidance to fix known defects or enhance functions.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Company Advantages – Professional Solutions & High-Quality Products

Professionalism and Experience

Customer-Oriented Service

Product Diversity

Advanced Technology and Equipment

Superior Geographical Location

Good Corporate Reputation