PROSOFT MVI46-MNET Ethernet Communication Module

PROSOFT MVI46-MNET

1. Overview

2. Key Specifications

- Operating Voltage: 24V DC

- Communication Speed: 10/100 Mbps (auto-sensing)

- Physical Interfaces:Memory Capacity: Approximately 5000 words of register space for data mapping between the PLC and Modbus network

- 1 x RJ45 port (10/100Base‑TX Ethernet)

- 1 x 25‑pin SLC backplane connector

- Temperature Range: -25°C to +55°C (industrial‑grade)

- EMC Compliance: Conforms to relevant industrial standards, suitable for harsh electrical environments

3. Product Features

-

Native Compatibility

Designed to integrate directly with the SLC processor backplane, eliminating the need for additional conversion hardware or complex wiring.

-

Flexible Data Mapping

With 5000 words of register space, the MVI46-MNET allows flexible configuration of data mapping tables via PC software, enabling customized data exchange between the PLC and Modbus TCP/IP devices.

-

High Real-Time Performance

Supports high‑speed Ethernet communication with low data exchange latency, making it ideal for industrial automation applications requiring fast and reliable data transfer.

-

Comprehensive Diagnostics

Equipped with multiple status LEDs and built-in self‑test functions, simplifying on-site troubleshooting and maintenance.

4. Structure and Components

-

Controller

The core processing unit responsible for protocol conversion and data handling.

-

Ethernet Port (RJ45)

Connects to the network switch using standard CAT5/CAT6 Ethernet cable.

-

Backplane Interface (25‑pin)

Directly plugs into the side slot of the SLC PLC, providing seamless integration with the SLC backplane.

-

Power Supply Module

Draws 24V DC power from either the SLC processor or an external power source.

-

Indicator LEDs

Include power, communication status, and fault indicators to provide at-a-glance module status information.

5. Typical Applications

-

Legacy System Upgrade

Enables older SLC-based systems to connect to modern Ethernet networks, facilitating seamless data exchange with upper‑level SCADA and HMI systems.

-

Remote Monitoring & Control

Allows remote data read/write and control of the PLC over the network, improving operational visibility and reducing on-site intervention.

-

Cross-Platform Data Exchange

Facilitates communication between Allen‑Bradley SLC controllers and devices from other manufacturers (e.g., Siemens, Schneider) using the Modbus TCP/IP protocol.

-

Industrial Internet of Things (IIoT)

Functions as an IIoT gateway, pushing real-time PLC data to cloud platforms, data centers, or MES/ERP systems for advanced analytics and decision support.

6. Installation and Maintenance

Installation

-

Hardware Installation

Power off the system, then insert the MVI46-MNET into an available slot on the SLC processor backplane.

-

Network Connection

Use a CAT5/CAT6 Ethernet cable to connect the module’s RJ45 port to a network switch.

-

Power Verification

Power on the system and verify that the module’s power LED illuminates, indicating proper power supply.

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

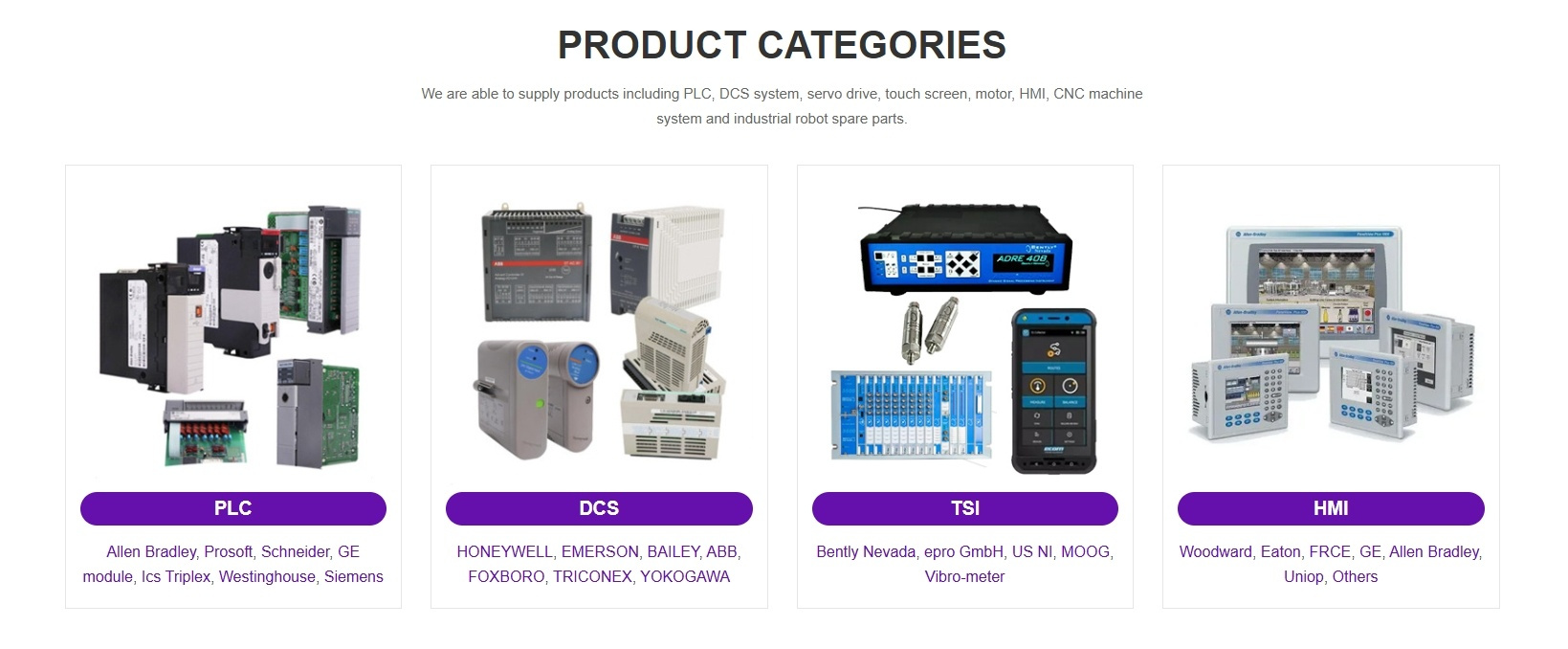

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Xiamen Xingruijia Export Co., Ltd. Product Introduction & Service Commitments

Covered Brand Portfolio

Core Business Scope

Service Commitments

A. Product Quality & Pricing Commitment

B. Production Standard & Service Life Guarantee

C. Professional Product Selection Guidance

D. Efficient Delivery Assurance

E. After-sales & Warranty Terms

Company Strength & Cooperation Concept