Welcome to our websites!

PROSOFT MVI46-PDPMV1 Master Module

PROSOFT MVI46-PDPMV1

1. Overview

The PROSOFT MVI46-PDPMV1 is a PROFIBUS DP-V1 Master module designed to enable high-speed data transfer between Rockwell SLC processors (such as the SLC 500 series) and PROFIBUS DP networks using proprietary backplane technology. The module supports Class 1 and Class 2 DP-V1 services for acyclic parameter data, allowing the SLC processor to directly access I/O data from devices on the PROFIBUS network.

2. Key Specifications

- Communication Protocol: PROFIBUS DP-V1 (compliant with IEC 61158)

- Host Compatibility: Designed for SLC processors (e.g., SLC 500 series)

- Backplane Compatibility: 1746 backplane

- Network Type: PROFIBUS DP 1.0 (primarily used for remote I/O systems)

- Maximum Baud Rate: 12 Mbps (supports high‑speed data transfer)

- Memory: On‑board database for data exchange and mailbox communication

- Operating Environment: Industrial-grade, supporting temperatures from -40°C to +85°C

3. Product Features

Proprietary Backplane Technology: Enables high-speed, direct communication between the SLC host and the PROFIBUS network, delivering higher efficiency than traditional gateways.

- Master-Only Operation: Functions exclusively as a PROFIBUS Master and does not support Slave mode.

- Ladder Logic Access: Allows direct reading and writing of PROFIBUS I/O data within the SLC processor’s ladder logic.

- Asynchronous Data Transfer: Supports asynchronous communication between the SLC processor and PROFIBUS devices.

- Write Protect Function: Prevents accidental firmware overwrites by disabling flash memory writes by default. This feature can be configured via jumpers to enable firmware updates in remote racks.

- Diagnostic Capabilities: Provides online diagnostics, CRC checking, and front-panel status LEDs for easy troubleshooting.

4. Structure and Components

- Module Main Body: Installs in an SLC processor slot and includes the backplane interface.

- Jumpers: Located on the rear of the module for configuring write‑protect mode and network parameters such as station address and baud rate.

- Front-Panel LEDs: Typically include power and communication status indicators to show module operation.

- Internal Database: Caches network data and manages mailbox communication.

5. Application Areas

- Petrochemical Industry: Connects large distributed control systems (DCS) with field instruments.

- Power Systems: Used for remote I/O communication in substations.

- Process Automation: Ideal for factory automation systems requiring high reliability and real‑time performance.

- SCADA Systems: Serves as a low‑level I/O interface for monitoring and controlling field devices from a host system.

6. Installation and Maintenance

Installation Steps

- Preparation: Ensure the SLC processor and PROFIBUS devices are ready, and back up the system configuration.

- Hardware Installation: Insert the MVI46-PDPMV1 into an available slot on the SLC backplane and secure it properly.

- Jumper Configuration: Set the rear jumpers according to the network parameters (station address, baud rate, etc.).

- Software Configuration: Use ProSoft’s Configuration Builder tool on a PC to configure the module and download the settings to the SLC processor.

- Wiring: Connect PROFIBUS devices (such as I/O modules and frequency converters) using standard PROFIBUS cabling.

Maintenance Notes

- Write Protection: It is recommended to keep the write‑protect jumper enabled during normal operation to prevent accidental firmware changes.

- Remote Updates: If firmware updates are required in a remote rack, follow the manual instructions to disable write protection temporarily.

- Diagnostics: Monitor communication status through the front‑panel LEDs and diagnostic tools in the SLC software to address issues promptly.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

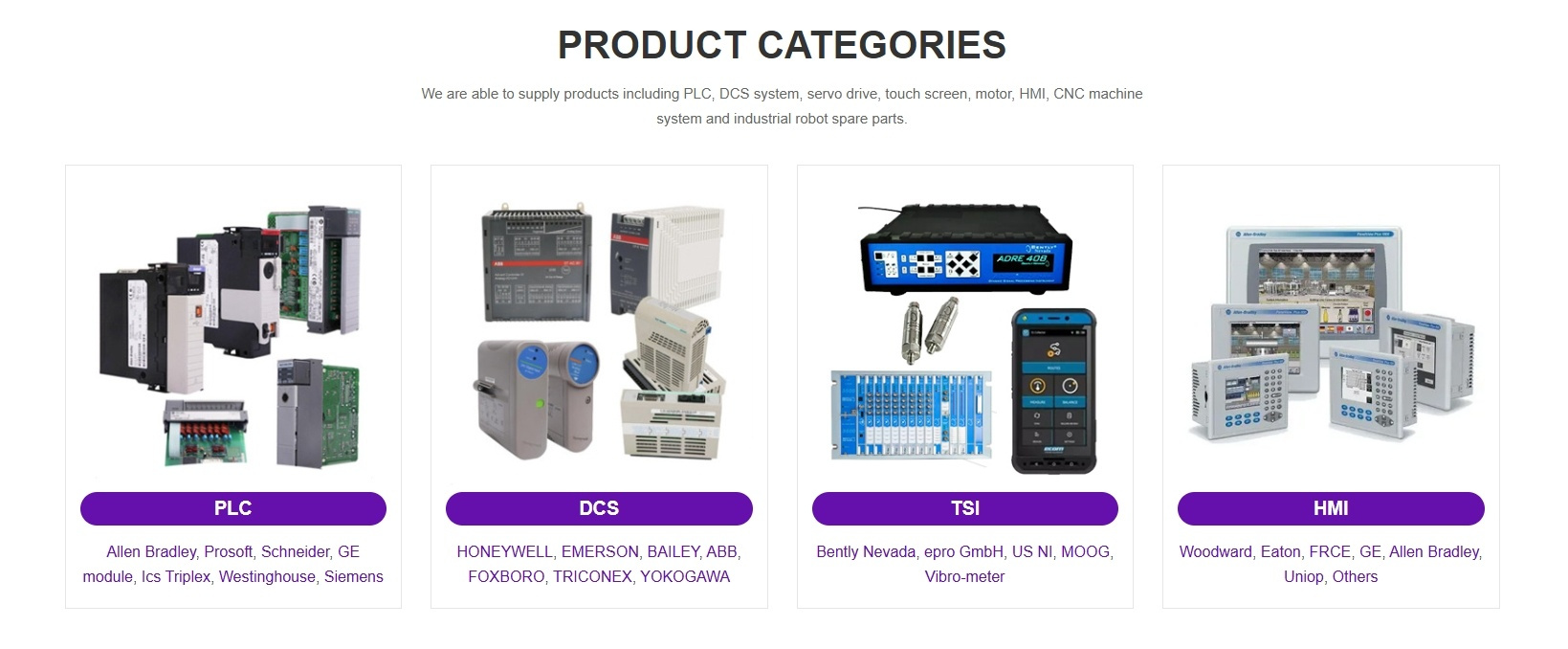

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Xiamen Xingruijia Export Co., Ltd. Product Introduction & Service Commitments

Covered Brand Portfolio

Main Products of the Company: Brands including FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Aen-Brady, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westinghouse, WOODWARD, Motorola, Rexroth, SEW, etc.

Core Business Scope

Core Business Scope: Spare parts for four major systems (DCS, PLC, Robots, and Large Servos) of various well-known brands. (100% original imported genuine products, professional supply of discontinued accessories)

Xiamen Xingruijia Export Co., Ltd. sincerely hopes to establish long-term and stable business relationships with various units. We are committed to supplying various specifications and models of instruments and meters, contributing to the development of business partners with high-quality and low-cost products and excellent after-sales service.

Service Commitments

A. Product Quality & Pricing Commitment

We wholeheartedly provide customers with products of stable quality and satisfactory after-sales service. On the premise of ensuring product quality, we strive to supply products at reasonable and low prices.

B. Production Standard & Service Life Guarantee

We organize supply in accordance with national standards or industry standards to ensure that product quality meets relevant requirements. Under correct usage conditions, the service life of our products will not be lower than that of other similar products.

C. Professional Product Selection Guidance

We assist customers in scientifically and reasonably selecting product types, specifications and models.

D. Efficient Delivery Assurance

We guarantee timely delivery. Under normal circumstances, goods will arrive within 6 working days; in special cases, the delivery time will be negotiated according to customer needs.

E. After-sales & Warranty Terms

Since all goods are produced by original foreign manufacturers, the after-sales service is provided by the manufacturers. The warranty period generally ranges from six months to one year, and the specific warranty period shall be subject to that provided by the original factory. In case of product quality problems, if both parties confirm that the problem is caused by the manufacturer’s quality, we will send the product back to the original manufacturer for repair or other necessary treatments.

Company Strength & Cooperation Concept

The company has strong strength, complete equipment, perfect testing methods, reliable quality and superior performance. Adhering to the tenet of putting users first, we insist on strict delivery deadlines, reasonable price standards, excellent product quality and proper after-sales service. We have long-term, sincere and effective cooperation with a large number of new and old users. Our products have demonstrated reliable performance and distinctive advantages, winning the trust and welcome of customers.

Write your message here and send it to us