Welcome to our websites!

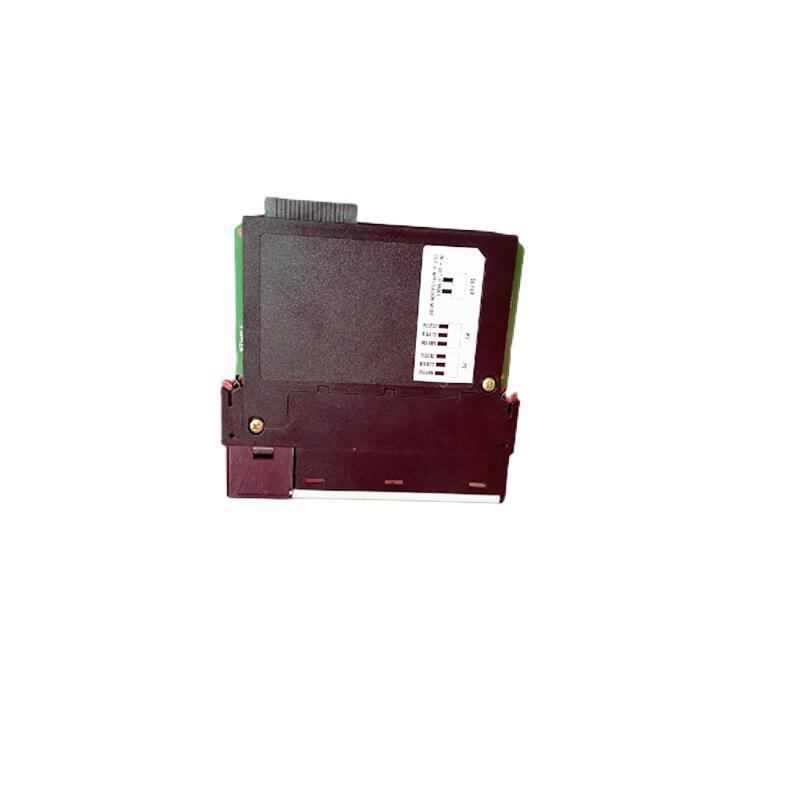

PROSOFT MVI56-LTQ Communication Module

PROSOFT MVI56-LTQ

Overview

The MVI56-LTQ module is a communication unit engineered by ProSoft Technology specifically for process control applications. Leveraging the EtherNet/IP protocol, it converts digital signals from programmable logic controllers (PLCs) into control commands compatible with Limitorque valves, enabling precise valve regulation and real-time status monitoring.

Specifications

The MVI56-LTQ is fully compatible with Allen-Bradley ControlLogix series CPUs, operating on the EtherNet/IP (Ethernet Industrial Protocol) communication standard. It requires a 24 VDC power supply and draws a maximum input current of 2 mA, with a wide operating temperature range spanning from -25°C to 60°C, making it suitable for diverse industrial environments.

Key Features

The module delivers high compatibility as it is exclusively designed for Limitorque valves and supports the standard command sets of multiple valve types, ensuring seamless integration with existing valve systems. Built with ProSoft’s industrial-grade design, it offers exceptional reliability, boasting resistance to vibration and electromagnetic interference, which allows it to perform stably in harsh industrial conditions. It enables easy programming through seamless integration with Studio 5000 programming software, streamlining the communication configuration process and reducing setup time for technicians. Additionally, it supports remote management capabilities, allowing operators to monitor valve status, conduct fault diagnosis, and execute remote control operations without on-site intervention.

Structure and Components

At its core, the MVI56-LTQ features a dedicated communication interface chip that handles the encapsulation and decapsulation of EtherNet/IP protocol data, ensuring efficient data transmission between the PLC and valves. A built-in power management module is responsible for power supply regulation and power conversion, guaranteeing stable power delivery to all internal components. Input/output terminals facilitate secure connections between the PLC backplane and the signal lines of Limitorque valves, ensuring reliable signal transfer. Encased in an industrial-grade housing, the module is protected against external mechanical damage and electromagnetic interference, preserving the integrity of internal circuitry even in demanding operational settings.

Application Areas

In the petrochemical industry, the MVI56-LTQ plays a critical role in the precise regulation of fluid flow within pipelines, contributing to safe and efficient production processes. Within the power sector, it is widely used for controlling steam flow in boilers and power plants, helping to optimize energy generation and maintain operational stability. For water treatment facilities, it provides accurate control over valves in both municipal water supply and wastewater treatment systems, supporting efficient water resource management. In the manufacturing industry, it manages pneumatic valves across various production lines, enhancing process automation and overall production efficiency.

Installation and Maintenance

Installation of the MVI56-LTQ is straightforward, as the module can be directly inserted into a slot on the ControlLogix backplane; technicians should ensure a firm and secure connection between the backplane and the module to avoid communication disruptions. Thanks to its modular design, maintenance is simplified: faulty units can be easily unplugged and replaced, and fault diagnosis can be performed quickly without complex procedures. For long-term operational stability, it is recommended to conduct regular inspections of connection cables, checking for tightness and corrosion to maintain consistent communication performance and extend the service life of the module.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Frequently Asked Questions

Q1: What is the earliest delivery time you can offer?

A: We will arrange shipment immediately upon receipt of your payment.

Q2: Do you have any overseas branches?

A: We do not have overseas branches, but our products are sold to customers all around the world.

Q3: Are you a manufacturer or a trader?

A: We are a trading company.

Q4: Can you provide technical support?

A: No, we only supply hardware products and do not include technical support services.

Q5: Can you provide data sheets/literature/technical documents?

A: Data sheets will be delivered together with the goods.

Our Services

Packaging and Shipping

We will arrange shipment within 3 working days after receiving your payment. All goods are strictly inspected before shipment to ensure product quality. Every product comes in a brand-new, original factory-sealed individual inner box. We can ship your order via major courier services including DHL, TNT, UPS, EMS and FedEx. Please contact us directly, and we will deliver the goods according to your specific requirements.

Warranty and Return Policy

All products we sell are 100% new and packed in original factory packaging, and each unit undergoes strict inspection before shipment. We strive to minimize any potential quality issues to the greatest extent possible. We provide a 12-month warranty period starting from the date of package receipt. If a product has defects in craftsmanship or materials, please contact us first, and we will arrange a replacement or offer alternative solutions for you to choose from. Shipping and handling fees are non-refundable. Customers shall be responsible for all costs incurred due to unreasonable returns and re-shipments. All returned items must be in good condition and maintain a resalable state. No warranty is provided for damages caused by human factors, such as breakage and scratches. Thank you for your understanding and cooperation.

Write your message here and send it to us