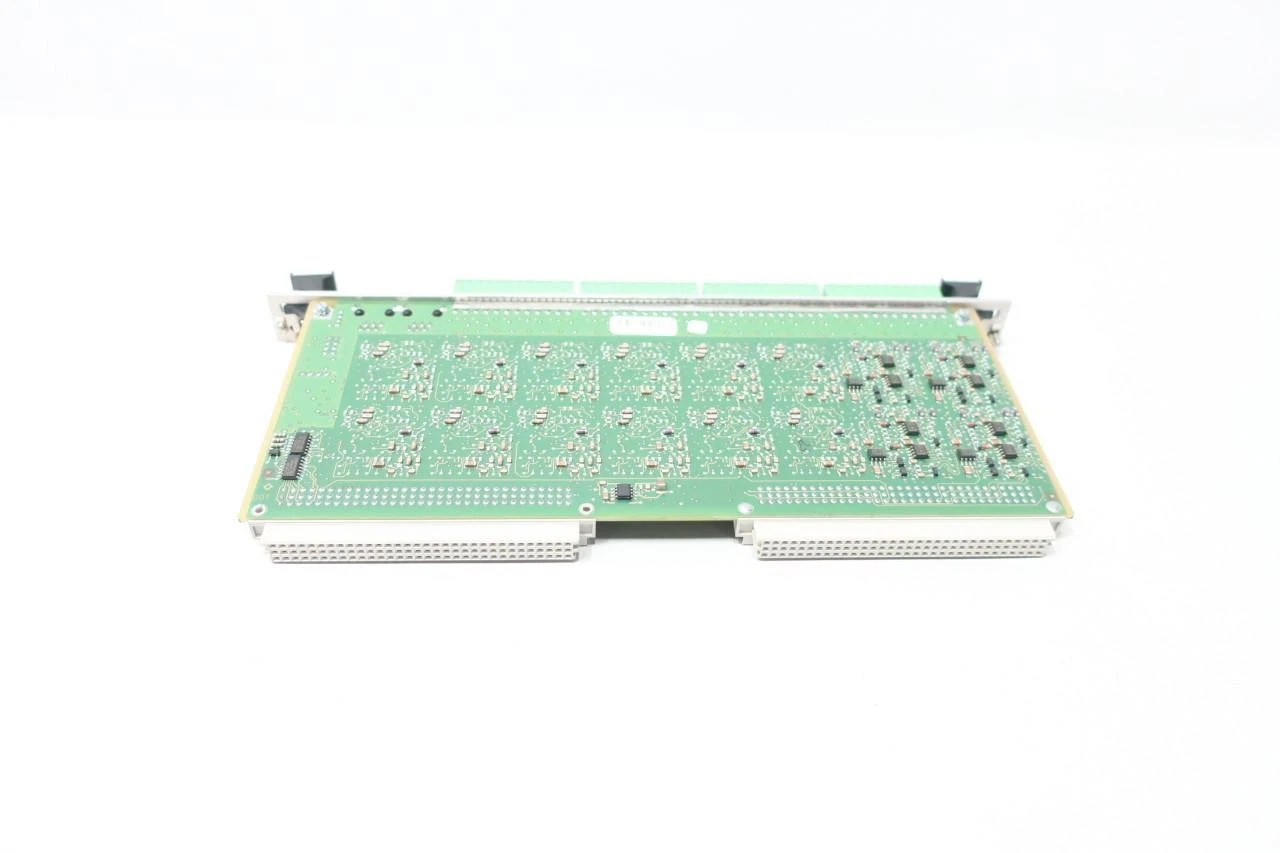

Vibro Meter 200-565-101-013 Diagnostic Module

Vibro Meter 200-565-101-013

Vibro Meter 200-565-101-013 is a vibration monitoring and condition diagnosis module designed for industrial sites. It belongs to the I/O card/monitoring module of the Vibro‑Meter (now part of Meggitt) VM600 series. Featuring a modular design, the product can be installed via DIN rail or panel mounting. It enables real-time vibration collection, analysis, and alarm for mechanical equipment, helping users implement predictive maintenance and fault diagnosis.

Key Technical Specifications

- Model/Part Number: 200‑565‑101‑013 (compatible with the main unit 200‑565‑000‑013)

- Input Type: Supports voltage or current signals from IEPE, ICP, and Charge sensors

- Frequency Response: 0.5 Hz ~ 20 kHz, covering conventional mechanical vibration frequency bands

- Output Signal: Voltage, 4‑20 mA, or digital (RS485/Modbus optional)

- Power Supply: 24 V DC ±10%, typical power consumption < 2.5 W

- Operating Temperature: ‑20 °C ~ +70 °C; Storage Temperature: ‑40 °C ~ +85 °C

- Dimensions/Weight: Approximately 120 × 100 × 45 mm, about 0.5 kg

- Protection Class: IP20, suitable for general industrial environments

- Certifications: CE, UL, and other international safety standards

Product Features

- High-Precision Measurement: Adopts advanced sensing and signal processing technology to accurately capture micro-vibrations and provide multiple parameters such as velocity, acceleration, and displacement.

- Versatile Output: Supports both analog (voltage/4‑20 mA) and digital (Modbus) outputs, facilitating integration with PLC, SCADA, and other systems.

- Modular & Expandable: Multiple cards can be stacked to form a multi-channel system. Supports DIN rail or panel mounting for flexible adaptation to different on-site requirements.

- User-Friendly: Equipped with an intuitive human-machine interface and easy-to-use software configuration tools for quick parameter setting and alarm threshold configuration.

- High Reliability: Industrial-grade design with anti-interference and high-temperature resistance, suitable for harsh working conditions.

Structure and Composition

- Main Card: Includes signal conditioning circuits, A/D converter, microprocessor, and communication interface.

- Power Module (Optional): 24 V DC power supply with low power consumption.

- Mounting Bracket: DIN rail or panel fixing accessories.

- Connection Terminals: For connecting IEPE/ICP/Charge vibration sensors.

- Indicators/Display Screen: Local status indication and fault alarm.

Typical Application Fields

- Vibration monitoring of key equipment in large industrial facilities such as power plants, petrochemical plants, oil refineries, and metallurgical plants.

- Condition monitoring and predictive maintenance of mechanical manufacturing, CNC machine tools, and automobile assembly lines.

- Structural health monitoring of transportation (e.g., railways, ships).

- Equipment health assessment for production lines in pulp, textile, printing, and other industries.

Installation and Maintenance Guidelines

- Installation: Use DIN rail or panel mounting to ensure the card is level. Use shielded wires for sensor wiring and ensure proper grounding.

- Power Connection: Use a 24 V DC regulated power supply. Check that the current does not exceed the rated 150 mA (for some models).

- Sensor Placement: Select appropriate sensors (IEPE/ICP) based on equipment vibration characteristics and fix them at key positions (e.g., bearings, gearboxes).

- Parameter Configuration: Set sampling rate, frequency range, alarm thresholds, and communication protocols (Modbus/RS485) via supporting software.

- Regular Inspection: Check wiring and terminal tightness every 6‑12 months, clean dust, and calibrate sensor sensitivity.

- Firmware Update: Pay attention to firmware versions released by the manufacturer. Update via USB/network interface when necessary to obtain the latest functions and security patches.

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

What Sets Us Apart

- Authenticity Guaranteed: We exclusively supply 100% original imported products, with strict quality checks to ensure compliance with original manufacturer standards, eliminating the risk of counterfeits.

- Obsolete Parts Specialists: We excel in sourcing hard-to-find, discontinued industrial components—solving critical replacement challenges for clients with legacy equipment.

- Swift & Reliable Delivery: Leveraging our optimized logistics network, we ensure fast shipment and accurate lead time estimates, minimizing operational downtime for our customers.

- Direct Sourcing & Strong Inventory: As a direct source supplier, we cut out unnecessary middlemen. Our in-stock inventory exceeds 100 million RMB, enabling immediate fulfillment of most orders.

Frequently Asked Questions (FAQs)

Q: Is there a warranty for the products you sell?

Q: Do you offer technical support for the components you supply?

Q: Do you maintain your own inventory, or do you only act as a trading intermediary?

Q: Are the products you offer new and original, or are they refurbished?