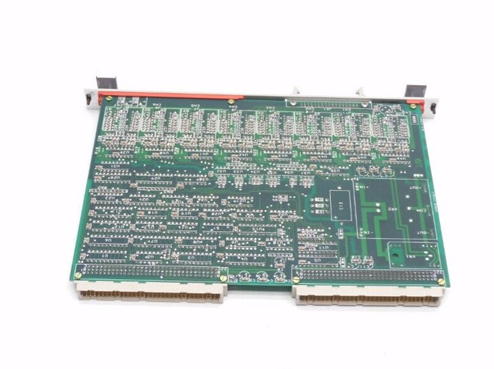

Xycom XVME-674 Processor Module

Xycom XVME-674

The XVME‑674 is a single‑slot VMEbus CPU/processor module launched by XYCOM (now a subsidiary of ABB). It is designed for high‑reliability scenarios such as industrial automation, process control, manufacturing, and robotics. Adopting a PC/AT compatible architecture, it provides traditional PC computing capabilities while being compatible with the real‑time characteristics of the VME bus, enabling long‑term stable operation in harsh environments.

Key Technical Specifications

- Processor: 33 MHz 80486DX or 66 MHz 80486DX2 (some documents mention the Motorola 68040 at 25 MHz)

- Memory: Optional 4 MB, 16 MB, or 32 MB DRAM; some models are equipped with 2 MB SRAM

- Storage: Built‑in IDE hard disk controller and floppy disk controller, allowing direct connection of hard disks/floppy disks

- Display: VGA graphics controller that supports standard display output

- Interfaces: 2 × RS‑232 serial ports, 1 × parallel port, and VMEbus interruptor circuit (supporting 7 levels of interrupts)

- Power Supply: 220 V AC (some documents indicate 24 V DC)

- Operating Temperature: -40 °C ~ 85 °C, with military‑grade vibration and shock resistance

- Size/Weight: Single‑slot, 1.20 lb (approximately 0.55 kg)

Product Features

- High Reliability: Utilizes military‑grade components and has a wide temperature range, making it suitable for extreme industrial sites.

- Modular Expandability: Through VME slots, expansion cards for I/O, communication, and storage can be flexibly added to achieve customized functions.

- Multi‑Protocol Compatibility: Supports VME64x, VMEbus standards, and common industrial protocols (Ethernet, RS‑232/485, USB, etc.), and is compatible with XYCOM and other brands of VME devices.

- Developer‑Friendly: Provides a cross‑platform SDK and Linux/RTOS drivers to shorten the secondary development cycle.

- Hardware Health Monitoring: Built‑in sensors for temperature, voltage, etc., to realize predictive maintenance and fault early warning.

Structure and Composition

- CPU Motherboard: Contains the core processor, memory slots, VGA controller, and hard disk/floppy disk controller.

- VME Interface Card: Responsible for bus signal conversion, address mapping, and interrupt management.

- Power Module: Accepts 220 V AC (or 24 V DC) and provides internal voltage stabilization.

- Heat Dissipation System: Combines heat sinks and fans to ensure heat dissipation in high‑temperature environments.

- Expansion Slots: Reserved VME slots for subsequent insertion of I/O, communication, or memory cards.

Typical Application Fields

- Industrial Automation Control: PLCs, DCSs, and fieldbus gateways.

- Manufacturing and Robotics: Real‑time motion control and machine vision processing.

- Power and Energy: Power plant monitoring and power distribution automation.

- Process Control: Continuous production processes in chemical engineering, petroleum, metallurgy, etc.

- Military and Aerospace: Embedded computing platforms requiring high reliability and anti‑interference capabilities.

Installation and Maintenance Points

Installation

- Insert the module into the corresponding slot of a VME‑compliant chassis or backplane, and ensure the latch is securely locked.

- Connect the power cable, heat dissipation fan, and necessary external I/O (serial port, parallel port, Ethernet, etc.).

- Check the address mapping and interrupt configuration of the VME bus to ensure compatibility with the host computer or other modules.

Debugging

- After startup, check the BIOS/firmware version through VGA output or a remote terminal.

- Use the provided SDK or driver to conduct basic function tests (memory, storage, serial communication).

- Verify interrupt response and priority using a VME interrupt test tool.

Daily Maintenance

- Regularly check if the heat sinks and fans are dusty, and maintain good heat dissipation.

- Monitor the power supply voltage and internal temperature, and use the alarm thresholds of the hardware health monitoring module for early warning.

- Back up the firmware and configuration files; if necessary, the firmware can be upgraded via JTAG or serial port.

- For systems that have been shut down for a long time, it is recommended to perform a power‑on self‑test every 6 months to prevent startup failure caused by capacitor aging.

Troubleshooting

- Failure to Start: Check the power supply, slot latch, and VME bus power supply; use a diagnostic card to read error codes.

- Communication Abnormalities: Confirm the serial port/Ethernet cable, baud rate settings, and whether the VME interrupt is masked.

- Overheating: Clean the heat sinks, check the fan speed, or replace with a higher‑power heat dissipation solution.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Expertise and Industry Experience

Client-First Service Philosophy

Diverse Product Range

Cutting-Edge Technology and Equipment

Strategic Geographic Advantage

Strong Corporate Reputation