Eaton SL72S4SH3LANL7MNR25

Eaton SL72S4SH3LANL7MNR25 is a high-performance servo drive in the Xpert series servo drive system from Eaton Corporation, specifically a model in the SL7 series. Working in tandem with matching servo motors, this drive forms a complete servo solution for achieving high-precision and high-dynamic-response control of mechanical movements. The core function of Eaton SL72S4SH3LANL7MNR25 is to receive command signals from a host controller (such as a PLC or motion controller) and output precisely controlled current and voltage to drive the servo motor for accurate speed, torque, and position control.

| Parameter Name |

Parameter Value |

| Product Model |

SL72S4SH3LANL7MNR25 |

| Manufacturer |

Eaton |

| Product Type |

Servo Drive |

| Series |

Xpert SL7 Series |

| Rated Output Current |

To be parsed based on the model code; for example, “S4″ may correspond to ~4A RMS |

| Supply Voltage |

3-phase, 200-480 V AC |

| Control Modes |

Torque, Speed, Position Control |

| Feedback Types |

Supports EnDat 2.2, Hiperface, Resolver, Sin/Cos 1Vpp, etc. |

| Communication Interfaces |

Standard EtherCAT; optional PROFIBUS DP-V1, PROFINET, EtherNet/IP, MODBUS TCP (defined by options such as “LANL7″) |

| Safety Features |

Safe Torque Off (STO) (may be standard) |

| Protection Class |

IP20 (for cabinet mounting) |

| Operating Ambient Temperature |

0°C to 55°C (no derating) |

| Storage Temperature |

-40°C to 85°C |

| Mounting Method |

Wall-mounted or flange-mounted |

| Cooling Method |

Forced air cooling |

| Certifications |

cULus, CE, RoHS |

Structure and Composition

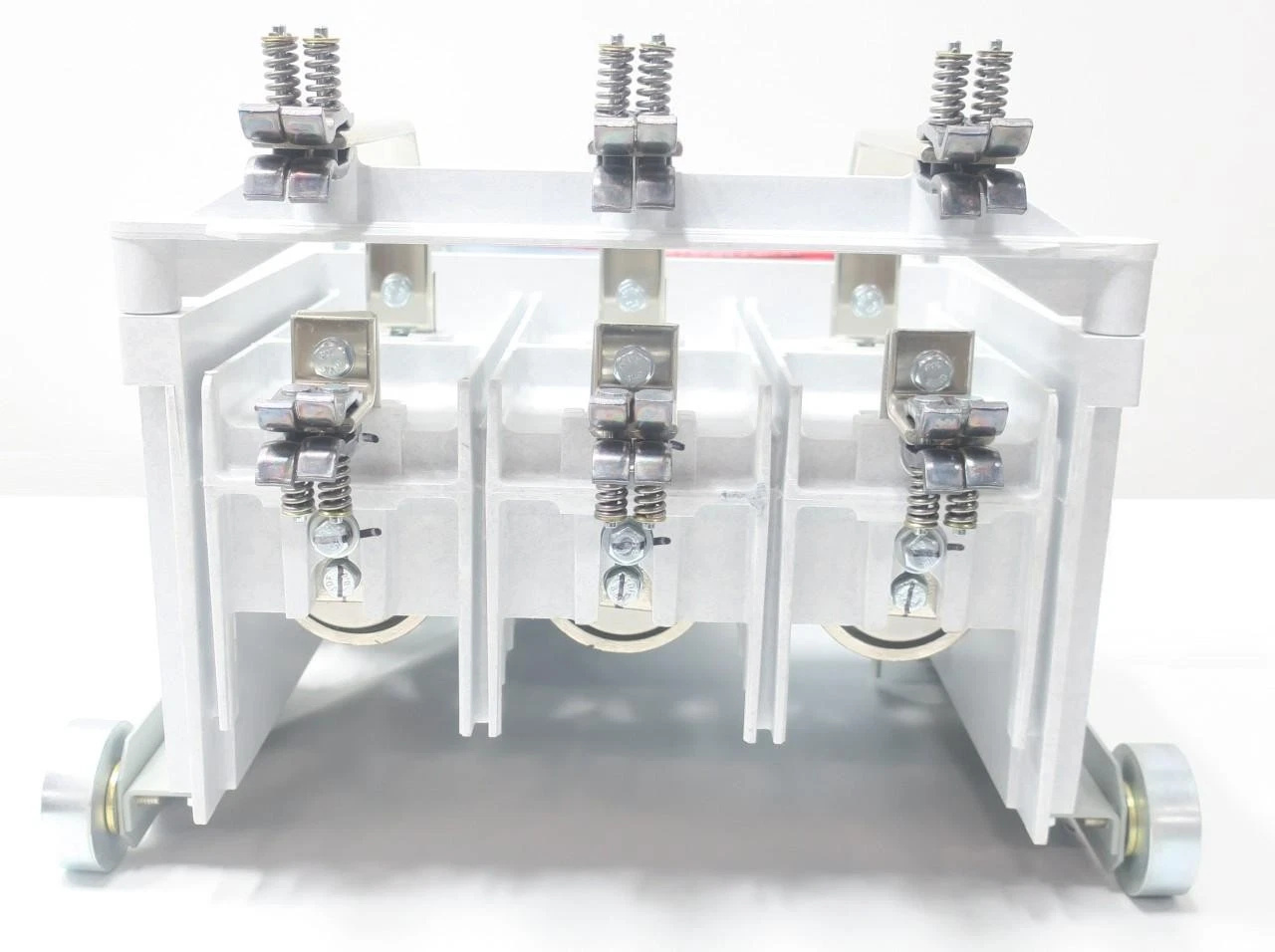

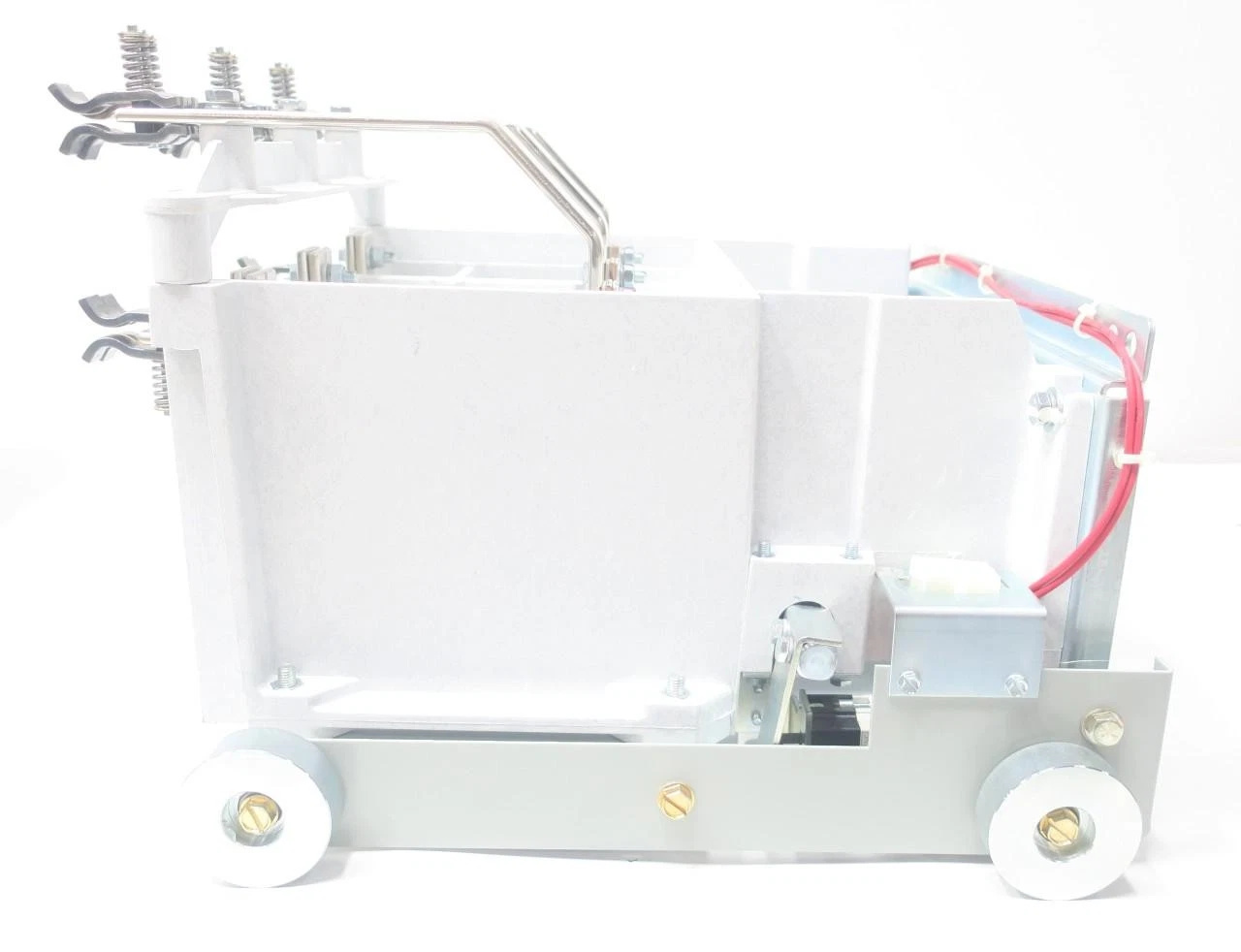

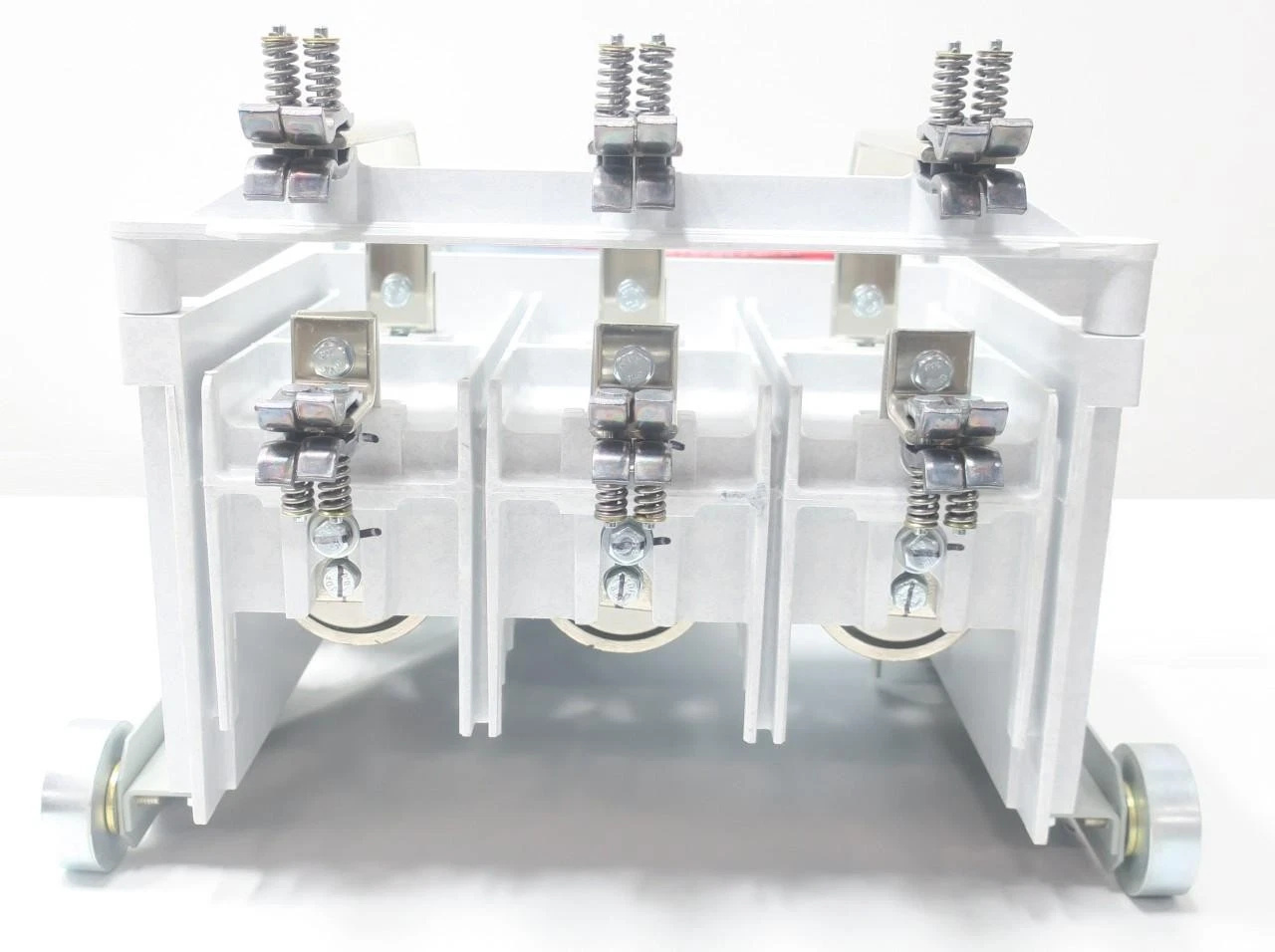

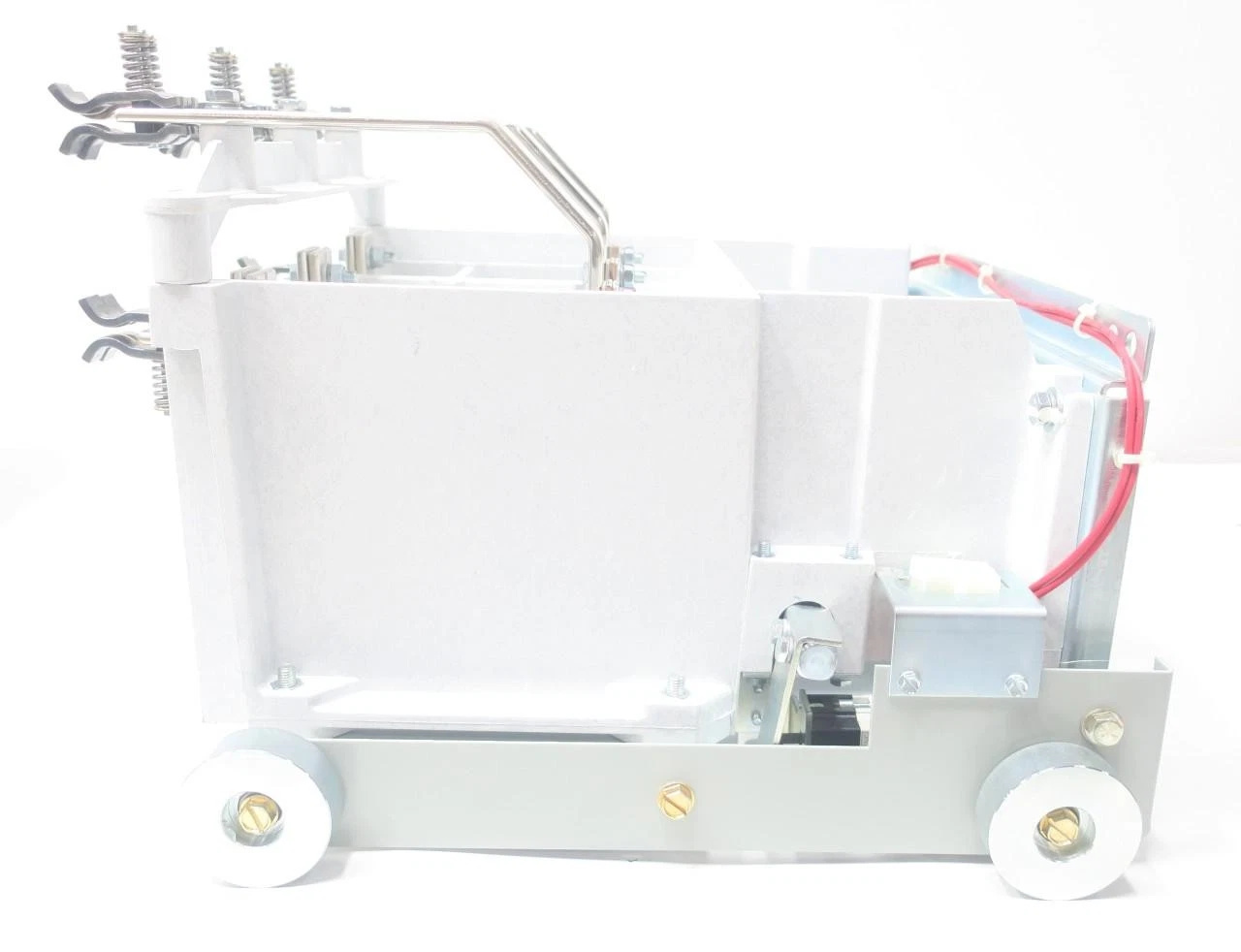

The Eaton SL72S4SH3LANL7MNR25 servo drive features a robust metal housing to ensure excellent electromagnetic compatibility (EMC) and heat dissipation performance. Its front panel is usually equipped with a digital display and navigation buttons for parameter setting, status monitoring, and fault diagnosis. The housing is designed with high-efficiency cooling fins and a built-in cooling fan to manage heat generated by power devices.

The internal structure mainly consists of the following functional modules: Rectifier and filter unit, which converts input three-phase AC power into DC power. Brake chopper (optional or built-in), used to consume energy generated during motor regenerative braking. Inverter unit, composed of IGBT or MOSFET power switching devices, which converts DC power into three-phase AC power with adjustable frequency and voltage through Pulse Width Modulation (PWM) technology to drive the servo motor. Control board, the “brain” of the drive, which includes a high-performance DSP (Digital Signal Processor) or microprocessor responsible for executing control algorithms, processing communication protocols, managing I/O interfaces, and handling motor feedback signals. Power supply circuit, which provides the required operating voltage for internal components. Communication interface board, which enables connection to the host network (such as EtherCAT). These components work synergistically through sophisticated circuit design and firmware programs to achieve precise and efficient control of the servo motor.

Key Features and Advantages

High Performance and Precision Control

Eaton SL72S4SH3LANL7MNR25 adopts advanced control algorithms to provide high-bandwidth current loop, speed loop, and position loop control. This ensures the system has fast dynamic response and extremely high steady-state accuracy to meet the most demanding positioning application requirements.

Excellent Usability and Integration

Parameter setting, debugging, and optimization can be easily performed through the intuitive front panel operation or PC-based software tools (such as Eaton’s SERVOsoft). The auto-tuning function can quickly match motor and load characteristics, simplifying the commissioning process. Rich communication options allow easy integration into various automation architectures.

Built-in Safety Features

Integrated Safe Torque Off (STO) function complies with EN/IEC 61800-5-2 standard. It enables basic safe shutdown without the need for external safety relays, improving system safety and simplifying design.

Strong Connectivity and Flexibility

Supports multiple mainstream industrial Ethernet and fieldbus protocols (determined by model options), facilitating distributed control and real-time data exchange. Its modular design allows users to select different functions and options according to specific application needs, providing high flexibility.

Application Areas

Eaton SL72S4SH3LANL7MNR25 servo drive is widely used in industrial automation fields requiring high dynamic performance and precise motion control. In packaging machinery, it is used to control transverse sealing, longitudinal sealing, flying cutting, and positioning filling to ensure precise cutting and packaging at high speeds. In material handling and assembly automation, it drives robots, linear modules, and sorting mechanisms to achieve fast and accurate pick-and-place operations. In metal processing machinery (such as bending machines and punch presses), it is used to control slider depth and feed length to ensure processing accuracy. In printing equipment, it is used for registration control and tension control to ensure printing quality. The Eaton SL72S4SH3LANL7MNR25 provides a reliable and efficient power and control solution for all occasions that require precise conversion of electrical signals into mechanical motion.

Installation and Maintenance

Pre-installation Preparation

Before installing the Eaton SL72S4SH3LANL7MNR25, ensure the power supply is completely disconnected. Carefully refer to the technical manual to confirm that the input power voltage matches the drive’s rated value. Plan the installation location to ensure sufficient space around for heat dissipation (follow the spacing requirements in the manual). Prepare appropriate cables (power, motor, brake resistor, communication cables) and ensure their specifications meet the requirements.

Maintenance Recommendations

Regularly inspect the Eaton SL72S4SH3LANL7MNR25 to check if the cooling fan is operating normally and if the radiator vents are unobstructed and free of dust. Use a multimeter to regularly check if the DC bus voltage is normal. View historical fault records and operating parameters through the drive’s front panel or software tools. Keep the drive dry and clean. In case of failure, first record the fault code and perform preliminary diagnosis according to the manual. Non-professionals are not allowed to open the drive housing as internal capacitors store high-voltage electricity, which is extremely dangerous.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our Strengths: All products are brand-new and original, backed by a one-year warranty and professional after-sales support! Every item in our company goes through rigorous quality inspections. We warmly welcome your inquiries and purchases—with your sincere intention, we’ll provide a more favorable price than competitors to help us secure orders together!

- Reach out to us for niche spare parts

- Contact us for rare spare parts

- Get in touch with us for discontinued spare parts

——————————————

Why do many of our products boast more competitive prices?(1) Direct procurement from sources minimizes price gaps caused by intermediate links(2) Stable supply channels ensure more reliable product availability

About Delivery Time(1) For in-stock products: Shipment will be arranged promptly once the contract is signed and payment is completed.(2) For custom-ordered products: Shipment will be dispatched in accordance with the quoted delivery timeframe.

Previous:

XYCOM 9465-KPM Operation Interface

Next:

Eaton 2150A84G01 Lfr-4 Low Voltage Circuit Breaker