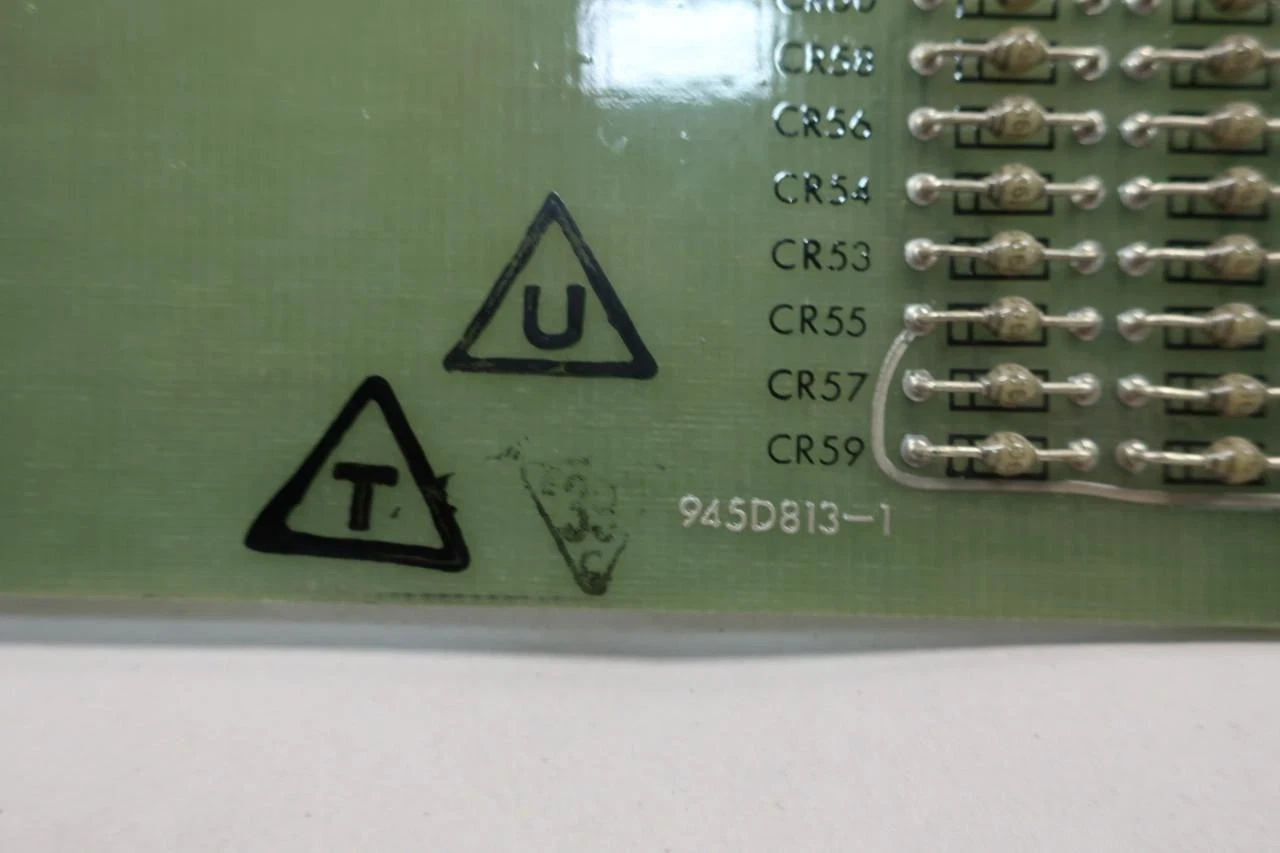

GE 115D2994G1 Circuit Board

GE 115D2994G1

GE 115D2994G1 is a Diode Voltage (Diode VT) circuit board manufactured by General Electric. It is a supporting PCB component used in industrial automation and power control systems. This board is mainly designed to realize functions such as diode rectification, voltage stabilization and voltage detection, and is commonly applied in scenarios including power distribution cabinets, variable frequency drives and servo systems.

Main Specifications

- Model: GE 115D2994G1

- Function: Diode Rectification/Voltage Detection Circuit Board (Diode VT)

- Operating Voltage Range: Compatible with 115 V AC (conventional industrial power distribution voltage)

- Rated Current: Ranging from 10 A to 30 A generally, depending on the specifications of the diodes on the board

- Dimensions: Standard DIN-rail mounting size, approximately 120 mm × 80 mm × 30 mm (including terminal block)

- Connection Method: Terminal block + screw wiring, compatible with conventional industrial junction boxes

Product Features

- High Reliability: Adopts industrial-grade thick copper cladding and moisture-proof and dust-proof housing, suitable for harsh working conditions.

- Modular Design: Can be directly inserted into the DIN-rail of the power distribution cabinet, facilitating quick replacement and maintenance.

- Multiple Protections: Built-in overvoltage and overcurrent protection circuits to prevent system failures caused by diode failure.

- Strong Compatibility: Complies with the interface standards of GE series control boards and can be seamlessly matched with other function boards of the GE 115D2xxx series (such as current amplification and current limiting boards).

- Easy Detection: Reserved test points on the board for on-site diagnosis and parameter calibration.

Structure and Composition

- PCB Main Body: Double-sided thick copper layer with a mixed layout of surface mount device (SMD) and through-hole components.

- Diode Array: Several power diodes (commonly used models such as 1N5408 and SB560) to achieve rectification and voltage stabilization.

- Voltage Detection Circuit: Voltage divider resistor network + operational amplifier, used for sampling and outputting monitoring voltage signals.

- Protective Components: Fuse, transient voltage suppressor (TVS) and thermistor.

- Terminal Block: DIN-rail terminal block with screws, divided into three groups: input, output and control.

- Housing: Metal or high-strength plastic housing, equipped with a protective cover and a grounding bolt.

Typical Application Fields

- Power Distribution Cabinets and Low-Voltage Power Distribution Systems: Realize rectification, voltage stabilization and voltage monitoring.

- Variable Frequency Drives and Servo Systems: Provide voltage-stabilized pre-stage rectification for power modules.

- Industrial Automation Control Cabinets: Combined with GE 115D2xxx series control boards to build a complete current/voltage monitoring and protection solution.

- Power Monitoring Instruments: Used as a pre-stage rectification/voltage sampling unit.

Installation and Maintenance Points

- Installation Location: Should be fixed on the DIN-rail of the power distribution cabinet, with good ventilation to avoid high-temperature accumulation.

- Wiring Requirements: Use copper core wires that meet the rated current. Confirm the polarity (input/output) before wiring, and tighten the terminal screws to prevent loosening.

- Grounding: The housing must be reliably grounded to prevent electric leakage.

- Inspection and Testing: Before the first power-on, use a multimeter to check whether the voltage at the input and output terminals meets the specifications. During operation, regularly check the fuse, terminal tightness and heat dissipation.

- Replacement Principle: If diode failure (such as overheating or open circuit) or tripping of protective components occurs, first cut off the power, remove the board, and replace it with a replacement part of the same model. Ensure all screws are reset to the original torque.

- Environmental Requirements: Operating temperature range of -20 °C to +55 °C, humidity ≤ 85% (non-condensing), and away from strong magnetic fields and strong vibrations.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our Company: Product Range & Service Pledges

Our Service Pledges to Customers

- Pledge 1: We are committed to delivering products with consistent quality and exceptional after – sales support. While upholding strict quality standards, we strive to offer competitive and reasonable pricing to maximize customer value.

- Pledge 2: All products are sourced or procured in compliance with national or industry standards, ensuring they meet the required performance criteria. When used correctly, our products will have a service life comparable to or exceeding that of other similar products on the market. We also provide professional guidance to help customers select the most suitable product types and specifications based on their specific requirements.

- Pledge 3: (Note: The original content for Pledge 3 was not provided. To ensure the completeness of our service commitments, we recommend supplementing details such as technical consultation, customization support, or post – purchase training here.)

- Pledge 4: We prioritize on – time delivery. Under normal circumstances, customers can expect to receive their orders within 6 working days. For special cases (e.g., urgent orders, custom parts), we will work with customers to negotiate a flexible delivery timeline that aligns with their needs.

- Pledge 5: Since all products are manufactured by original overseas factories, after – sales service is provided directly by these manufacturers. The standard warranty period typically ranges from 6 months to 1 year, with specific terms subject to the original manufacturer’s policies. If a product experiences quality issues, and both parties confirm the problem stems from the manufacturer’s defects, we will facilitate the return of the product to the original factory for repair or arrange alternative solutions (e.g., replacement) as needed.

About Our Company