Welcome to our websites!

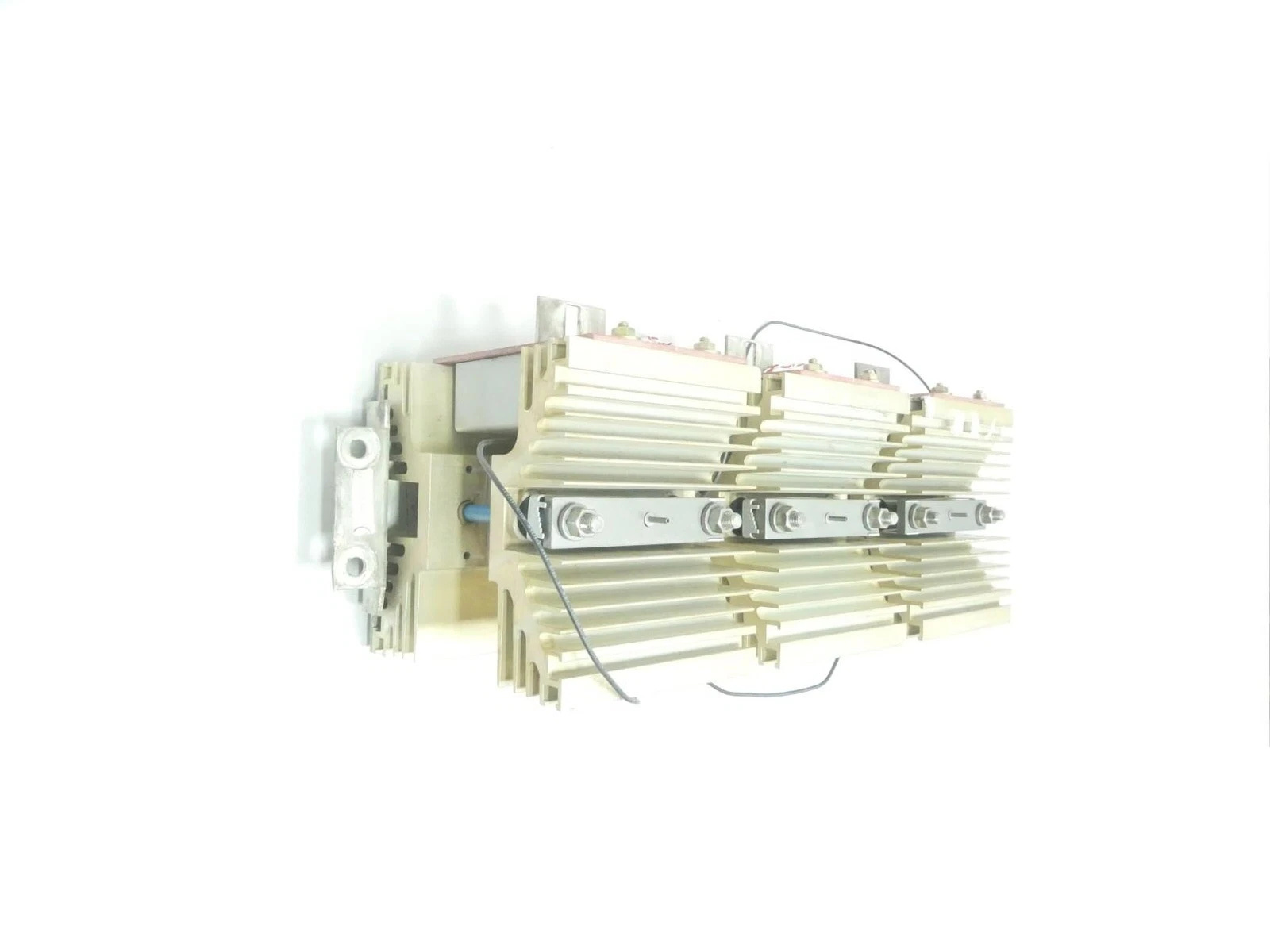

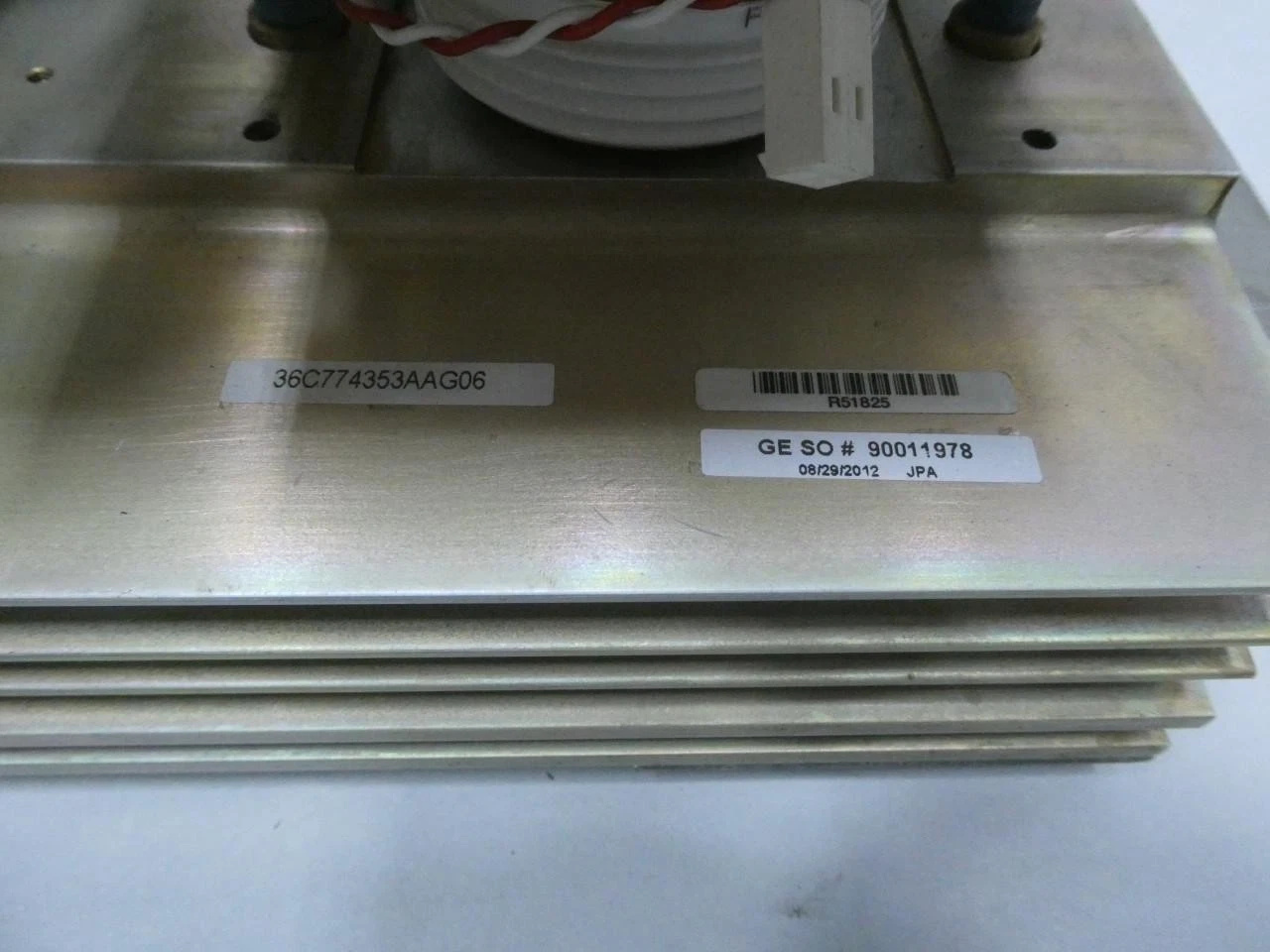

GE 36C774353AAG06 Stacking Module

GE 36C774353AAG06

1. Overview

GE 36C774353AAG06 is a Stack model under the GE B-Series bridge rectifier series. It adopts a 1 QL 153 structure and is equipped with a Ferrite ring to suppress high-frequency noise. This product plays a core role in converting alternating current (AC) to direct current (DC) in power electronic systems, featuring high current-carrying capacity and a reliable thermal management design.

2. Main Technical Parameters (Typical Values)

- Rated Voltage: Approximately 1.5 kV

- Rated Current: Approximately 150 A

- Power Capacity: Approximately 225 kW

- Package Type: Stacked module, compatible with standard DIN-Rail or cabinet installation

- Operating Temperature Range: -40 °C ~ +85 °C

- Cooling Method: Natural air cooling or forced air cooling

- Protection Class: IP20 (for indoor use)

3. Product Features

- High Reliability: Adopts thick-film diode technology, enabling high voltage resistance, impact resistance, and long service life.

- Low-Noise Design: Built-in Ferrite ring suppresses electromagnetic interference, complying with IEC EMC requirements.

- Modular Stacking: Current capacity can be flexibly expanded through stacking, facilitating system upgrades.

- Easy Maintenance: The modular structure allows quick unit replacement, reducing downtime.

- Strong Compatibility: Complies with GE B-Series standard interfaces and can be directly used with control modules such as GE D20-PS and D30-PS.

4. Structure and Composition

- Rectifier Unit: A bridge structure composed of several thick-film diodes.

- Ferrite Ring: Located at the input end of each stacked unit to suppress high-frequency noise.

- Terminal Block: Provides reliable electrical connection, supporting bolt or quick snap-on installation.

- Heat Sink/Radiator: Integral design of metal heat sink and housing, compatible with air-cooling or water-cooling systems.

- Housing: Metal frame with a protective cover, facilitating installation in cabinets or on DIN-Rails.

5. Typical Application Fields

- Industrial Power Supplies: Large inverters, servo drives, and motor control centers.

- Power Systems: Distribution transformers, UPS, and front-end rectification for inverters.

- Rail Transit: Rectification devices for traction power supply systems.

- Petroleum and Chemical Industry: High-power electrolysis and heating furnace power supplies.

- Renewable Energy: Front-end rectification for wind power and photovoltaic inverters.

6. Installation and Maintenance Points

- Pre-Installation Inspection: Confirm that the power voltage and rated current match the product specifications; check if the terminal connections are secure.

- Heat Dissipation Design: Ensure good contact between the heat sink and the cabinet or fan; install forced air cooling if necessary.

- Grounding Protection: The housing must be reliably grounded to prevent electric leakage and electromagnetic interference.

- Regular Inspection: Check the tightness of terminals and whether there is dust accumulation on the heat sink surface every 6 to 12 months.

- Replacement Strategy: If local overheating or diode failure occurs, stacked modules can be replaced in units to avoid overall machine shutdown.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Expertise and Industry Experience

With years of accumulated experience and professional technical prowess in the sector, we stand out as a reliable partner capable of delivering top-tier products and services to our clients. Our core focus lies in technological R&D and innovation, complemented by a well-established production line and strict quality control system—both of which work in tandem to ensure every product meets the highest standards of reliability and longevity.

Client-First Service Philosophy

We place great emphasis on effective communication with clients, enabling us to tailor solutions that align with their unique requirements. From pre-sales inquiries to after-sales support, our entire service process revolves around the client’s needs: we provide prompt responses and expert assistance at every step, ensuring an exceptional customer experience from start to finish.

Diverse Product Range

Our product offerings are extensive and span multiple industries, allowing us to cater to the varied demands of different clients. Whether it’s large-scale mass production or one-of-a-kind personalized customization, we have the capability to deliver high-quality solutions—all while ensuring our products offer outstanding value for money.

Cutting-Edge Technology and Equipment

We invest heavily in advanced production equipment and state-of-the-art technical processes, and we never stop upgrading our technical capabilities to stay ahead in the competitive market. Through continuous innovation and technical refinement, we consistently develop and manufacture products that hold strong competitive edges in the marketplace.

Strategic Geographic Advantage

Headquartered in Xiamen, we leverage the city’s prime geographic location and well-connected transportation and logistics network. This strategic advantage enables us to respond to the needs of both domestic and international clients more swiftly and efficiently, significantly reducing delivery lead times.

Strong Corporate Reputation

We have built a solid reputation within the industry, thanks to our commitment to integrity and a down-to-earth approach to business. This has not only earned us the trust of a large number of clients but also fostered long-term, mutually beneficial cooperative relationships with them.

Write your message here and send it to us