Welcome to our websites!

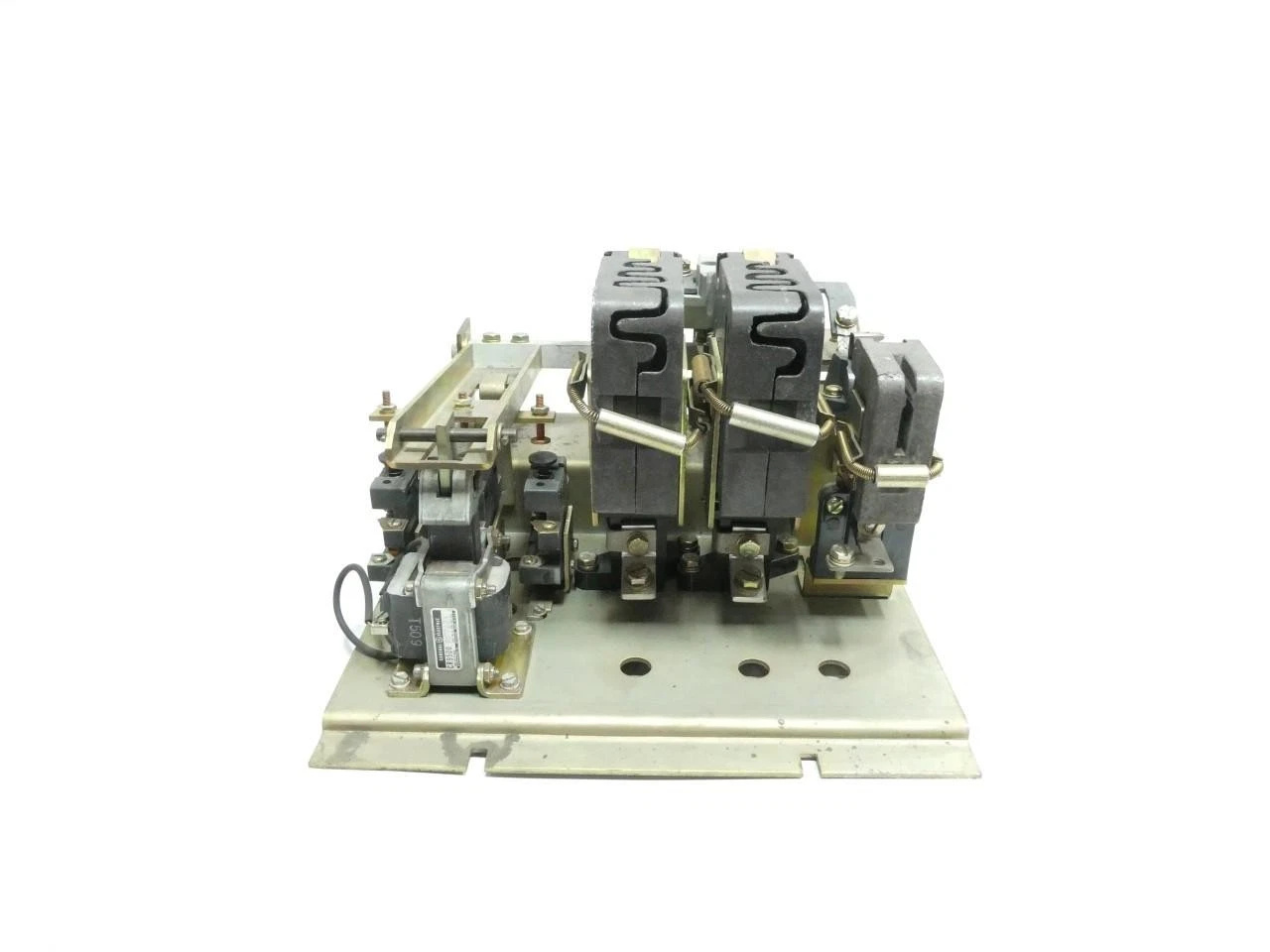

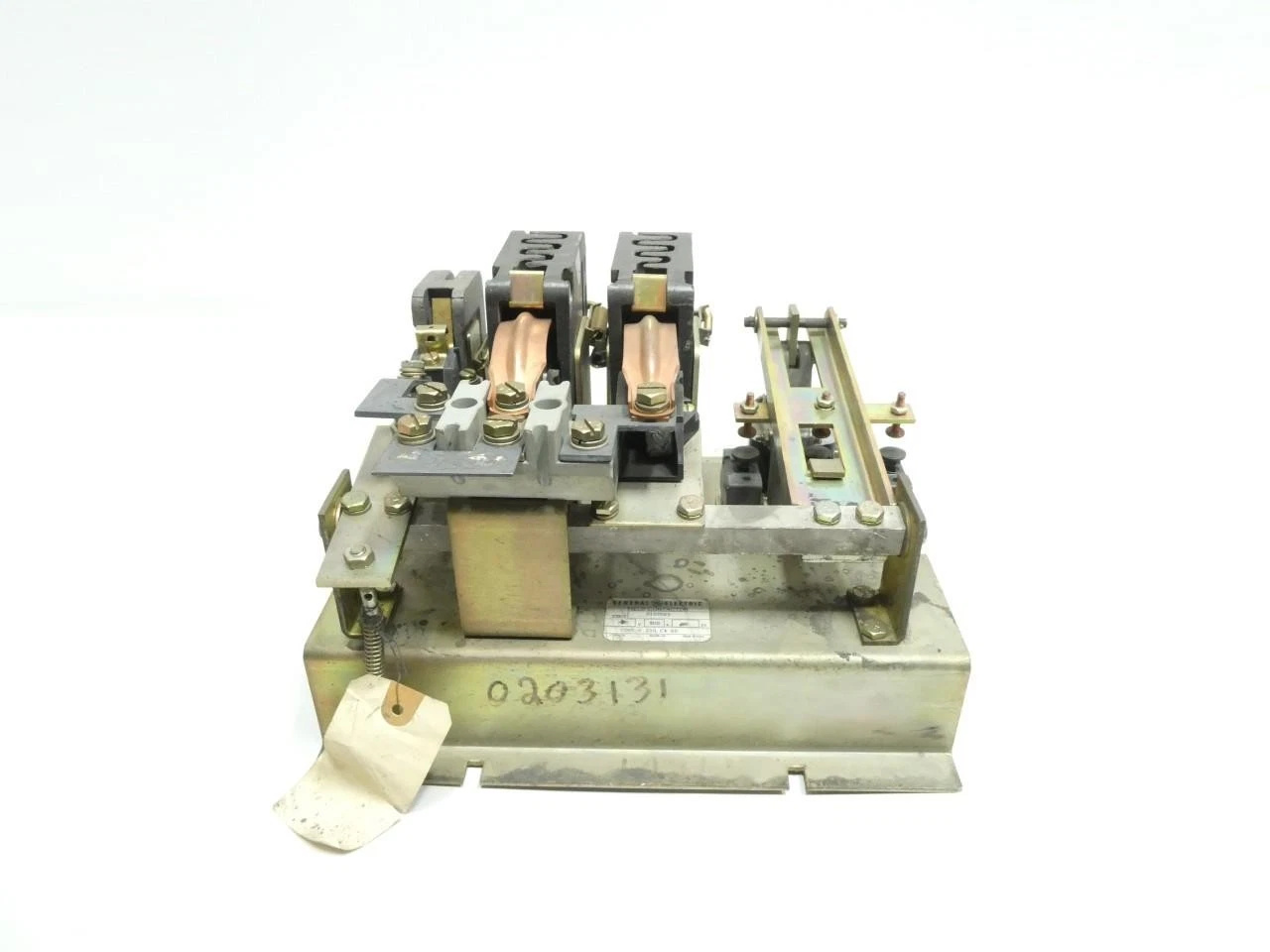

GE IC2812B107DA3 Field Contactor

GE IC2812B107DA3

Overview

GE IC2812B107DA3 is a 600 V class Motor Field Contactor manufactured by General Electric (GE), with a rated current of approximately 200 A. It is suitable for starting, stopping, and protecting AC motors. This contactor belongs to GE’s IC series of high-voltage electrical components, featuring a reliable mechanical structure and excellent electrical performance. It is widely used in industrial power distribution and automation systems.

Main Specifications

- Rated Voltage: 600 V AC (rated operating voltage)

- Rated Current: 200 A (normal operating current)

- Pole Number: 3 poles (compatible with three-phase motors)

- Contact Configuration: Normally Open (NO) contacts, with auxiliary contacts for signal feedback

- Mechanical Life: ≥ 100,000 operations

- Electrical Life: ≥ 50,000 operations

- Protection Class: IP 20 (for indoor installation)

Product Features

- High Reliability: Adopts high-temperature and corrosion-resistant alloy materials to ensure long-term stable operation in harsh environments.

- Fast Breaking: Short breaking time, which can effectively suppress electric arcs and protect motors and circuits.

- Modular Design: Standardized size, facilitating unified layout and replacement in power distribution cabinets.

- Auxiliary Contacts: Provides additional normally open/normally closed auxiliary contacts, enabling easy linkage with control systems such as PLCs and relays.

- Easy Maintenance: Simple structure and convenient disassembly and assembly, reducing maintenance costs.

Structure and Composition

- Main Contact Assembly: Includes main contact base, spring, and contact spring mechanism, responsible for on-off of main current.

- Auxiliary Contact Assembly: Provides signal feedback, often used for status indication or control circuits.

- Coil (Coil Box): Generates magnetic field to drive the main contacts to act after being energized, with a rated coil voltage of 230 V AC.

- Enclosure: Metal enclosure provides mechanical protection and electrical insulation.

- Mounting Flange: Used for fixing on power distribution cabinets or panels, achieving stable installation with bolts.

Typical Application Fields

- Industrial Automation: Motor control for CNC machine tools, packaging machinery, and conveyor systems.

- Power Distribution: Motor protection and control for power distribution cabinets and substation.

- Petroleum and Chemical Industry: Starting and stopping of large motors such as pumps and compressors.

- Building Facilities: Driving of high-power motors for air conditioning and ventilation systems.

- Mining Machinery: Motor control for heavy-duty equipment such as hoists and crushers.

Installation and Maintenance Points

Installation

- Confirm that the installation space in the power distribution cabinet meets the size of the contactor (standard 3-pole module).

- Use dedicated bolts to fix the flange on the power distribution cabinet or panel, ensuring the contactor is placed horizontally.

- Correctly connect the main circuit, auxiliary contacts, and coil power supply according to the wiring diagram, paying attention to phase sequence and grounding.

- Check that the coil voltage matches the power supply voltage to avoid coil damage caused by overvoltage or undervoltage.

Commissioning

- Before energization, check that all wiring is secure, without short circuits or incorrect connections.

- First, test the coil energization alone to see if it can pull in normally, then check the closing and breaking of the main contacts.

- Use an ammeter to monitor the starting current and ensure it does not exceed the rated value.

Daily Maintenance

- Regularly check the wear of contacts and replace the contact assembly if necessary.

- Remove dust and corrosives inside the enclosure to maintain good heat dissipation.

- Check the coil resistance to prevent overheating of the coil due to aging.

- Conduct functional tests on the auxiliary contacts to ensure accurate signal feedback.

Troubleshooting

- Failure to Pull In: Check the coil power supply, coil resistance, and terminal blocks; confirm that the coil is not burned out.

- Contacts Fail to Break: May be due to contact wear or spring failure, requiring replacement of the main contact assembly.

- Abnormal Noise or Heating: Check if the load exceeds the rated current or if there is looseness inside the contactor.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Expertise and Industry Experience

With years of accumulated experience and professional technical prowess in the sector, we stand out as a reliable partner capable of delivering top-tier products and services to our clients. Our core focus lies in technological R&D and innovation, complemented by a well-established production line and strict quality control system—both of which work in tandem to ensure every product meets the highest standards of reliability and longevity.

Client-First Service Philosophy

We place great emphasis on effective communication with clients, enabling us to tailor solutions that align with their unique requirements. From pre-sales inquiries to after-sales support, our entire service process revolves around the client’s needs: we provide prompt responses and expert assistance at every step, ensuring an exceptional customer experience from start to finish.

Diverse Product Range

Our product offerings are extensive and span multiple industries, allowing us to cater to the varied demands of different clients. Whether it’s large-scale mass production or one-of-a-kind personalized customization, we have the capability to deliver high-quality solutions—all while ensuring our products offer outstanding value for money.

Cutting-Edge Technology and Equipment

We invest heavily in advanced production equipment and state-of-the-art technical processes, and we never stop upgrading our technical capabilities to stay ahead in the competitive market. Through continuous innovation and technical refinement, we consistently develop and manufacture products that hold strong competitive edges in the marketplace.

Strategic Geographic Advantage

Headquartered in Xiamen, we leverage the city’s prime geographic location and well-connected transportation and logistics network. This strategic advantage enables us to respond to the needs of both domestic and international clients more swiftly and efficiently, significantly reducing delivery lead times.

Strong Corporate Reputation

We have built a solid reputation within the industry, thanks to our commitment to integrity and a down-to-earth approach to business. This has not only earned us the trust of a large number of clients but also fostered long-term, mutually beneficial cooperative relationships with them.

Write your message here and send it to us