XYCOM 9406-ACT Flat Panel Touch Display

XYCOM 9406-ACT

XYCOM 9406‑ACT (also written as 9406‑ACT, 9406‑AC) is a flat-panel touch display designed for industrial on-site applications, commonly used in Human-Machine Interface (HMI) and automated control systems. It features a 10.5-inch TFT color LCD with a resolution of approximately 800 × 480 (SVGA), optional resistive or capacitive multi-touch panels, excellent anti-interference and protection performance, making it suitable for long-term operation in harsh environments.

Main Technical Specifications

- Display Size: Approximately 10.5 inches

- Display Technology: TFT color LCD with 800 × 480 (SVGA) resolution

- Touch Method: Resistive or capacitive, supporting multi-touch functionality

- Environmental Rating: Front panel complies with NEMA 4/4X/12 protection standards, ensuring moisture resistance, dust resistance, and light impact resistance

- Power Supply/Interfaces: 24 V DC power input, equipped with multiple I/O ports, RS‑232, RS‑485, and Ethernet interfaces

- Display Mode: 3 1/2-inch LCD or LED display (optional)

- Structural Features: Three-chamber isolated structure and explosion-proof housing, suitable for harsh on-site working conditions; optional multiple sensor chips, supporting analog and digital signal output, compatible with HART communication protocol

Product Features

- Compact and Lightweight: Smaller and lighter than traditional HART instruments, facilitating direct on-site installation, reducing installation man-hours and costs.

- Reliable Protection: Three-chamber isolated structure and explosion-proof housing provide excellent moisture resistance, dust resistance, and impact resistance, suitable for high-temperature, high-humidity, or dusty environments.

- Multiple Touch Options: Supports resistive and capacitive touch, meeting the needs of different industrial sites.

- Communication Compatibility: Built-in HART protocol, providing both analog and digital signal output for easy integration with upper-level systems.

- Reverse Polarity Protection: The circuit is equipped with positive and negative reverse connection protection, preventing equipment damage even in case of wiring errors.

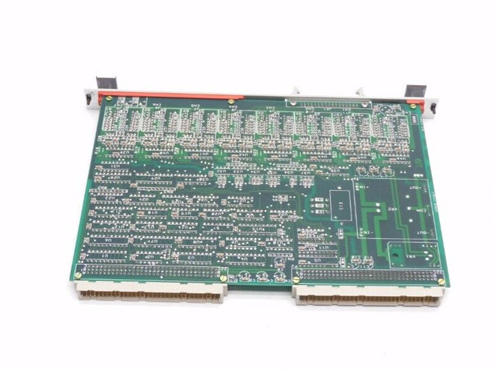

Structure and Composition

- Display Module: TFT LCD mainboard, providing graphic display and video output.

- Touch Layer: Resistive or capacitive touch sensor layer, cooperating with control chips to realize multi-touch.

- Control Mainboard: Built-in processor, communication interfaces (RS‑232/RS‑485/Ethernet), and power management circuit.

- Protective Housing: Metal or high-strength plastic housing complying with NEMA 4/4X/12 standards, with an internal three-chamber isolated design to enhance explosion-proof and dust-proof performance.

- Terminal Blocks: Wiring blocks for power supply, signal input/output, and communication ports, facilitating on-site wiring.

Typical Application Fields

- Process Control: On-site monitoring and parameter display for continuous production processes such as petroleum, chemical, and natural gas.

- Power System: Operation interface and status display for substations and distribution automation.

- Manufacturing: Operation panels for CNC machine tools and robot workstations.

- Water Treatment and Environmental Protection: On-site human-machine interaction for sewage treatment plants and waste gas monitoring systems.

- Transportation and Logistics: Monitoring and control of automated warehouses and conveyor systems.

Installation and Maintenance Guidelines

- Installation Location: Choose a well-ventilated area away from direct sunlight or strong magnetic fields, ensuring the front panel faces the operator.

- Fixing Method: Can be directly fixed at the measurement point or in the control cabinet using bolts or brackets; corrosion-resistant screws must be used to prevent rust.

- Wiring Inspection: Before connecting power, signal, and communication lines, always confirm the polarity. Utilize the device’s reverse polarity protection function to reduce the risk of incorrect connection.

- Protection Inspection: Regularly inspect the housing seals and terminal blocks to ensure the protection level is not compromised.

- Software Upgrade: If updating HMI software or firmware, use dedicated tools provided by the manufacturer. Avoid direct power plugging/unplugging during operation.

- Cleaning and Maintenance: Wipe the display panel with a soft dry cloth or special cleaning agent. Do not use cleaners containing alcohol or strong corrosive substances.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our Product Commitments

Ordering Process